M

AINTENANCE

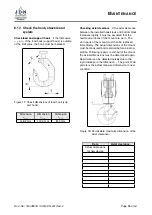

Adjusting overload protection

The adjustment

method described here is based on the attach-

ment of test loads (

,

→

Figure 14). The overload

protection is located in the control valve.

1. Attach overload of 125% of the load capacity.

2. If this overload is lifted, the adjusting bolt

(1)

must be adjusted clockwise until it is no

longer possible to lift the overload. If the over-

load is not lifted, the adjusting bolt must be

adjusted anticlockwise until it is possible to

lift the overload. Then it must be adjusted

back until it is no longer possible for it to lift

the overload.

3. After the adjustment process, it must be pos-

sible to lift 110% of the nominal load. A dy-

namic overload test of 110% of the nominal

load is therefore possible.

Figure 14: Adjusting overload protection

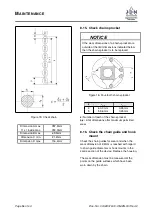

8.14. Check chain

WARNING

Danger from chain fracture

If the chain of your product

PROFI 25 TI

has one

of the features listed below, the chain may break

upon further use.

I

Do not use the product

I

Replace the chain

•

Corrosion pitting

•

Bent or damaged chain links

•

Chain drawn tight

•

Wear over 11 pitches (dimension A)

•

Single pitch wear (dimension B)

•

Diameter reduction of a chain link (dimension

C)

•

Elongation of a chain link (dimension D)

Check the entire length of the chain. When check-

ing the replacement limit, future wear up until the

next inspection date must be taken into account.

If the chain dimension values are outside the limit

values specified in the table when checked, the

chain has reached its replacement limit and must

be replaced by a new one.

The chain sprockets must also be replaced to-

gether with the chain, as otherwise the new chain

will be subjected to increased wear. Each chain

replacement must be documented in the inspec-

tion log.

Please observe the information contained in

,

→

DIN 685, Part 5

,

→

ISO 7592

Doc.-No.: VA049318-10-OM-EN-0319-64-2

Page

53

of 64