I

NITIAL OPERATION

Load case

Shock-

force-

factor

Force to support

construction

Nominal load

(25t)

1,1

269,8 kN

25% overload

(31,3 t)

1,1

337,2 kN

Table 1: Force to support construction

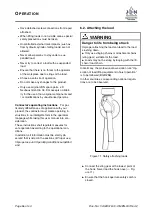

Figure 10: Securely attach the hoist

I

Provide a suitable working platform.

I

Hang the product on a carriage with the sup-

port hook or hang it up stationary.

I

Ensure that the hook aperture safety catch

closes automatically.

5.3. Connecting the power supply

The power supply for your product

PROFI 25 TI

takes place either centrally on the motor / connec-

tion block or on a service unit or filter regulator.

This is connected to the compressed air hose of

the power supply.

The supply of the control system takes place from

the control valve block.

1. Check air connection parts for dirt and clean

them if necessary.

2. Sparge the compressed air hose to remove

foreign bodies.

3. Connect the compressed air hose to the port.

Firmly mount the hose clamp. Screw on the

union nut.

5.4. Lubricating the chain

Before tests can be carried out, the chain must be

lubricated.

The chain of your product

PROFI 25 TI

must be

lubricated in the links in an unloaded state.

I

Clean heavily soiled chains.

I

Place the chain in a suitable container.

I

Spray the chain with a special lubricant or ve-

hicle engine oil.

If you want to lubricate the suspended chain, en-

sure that the chain links are oiled at the contact

points. Move the chain back and forth to do this.

During operation in areas with a high corrosion po-

tential, such as offshore, the chain can be largely

protected against corrosion by using speciality

lubricants. These types of lubricants are char-

acterised, among other things, by a weathering

resistance, water insolubility and good adhesion

properties.

The re-lubrication intervals are to be set depend-

ing on the exposure. Please contact us if neces-

sary.

5.5. Tests before commissioning

Your product

PROFI 25 TI

, including the support-

ing structure, must be tested by an expert prior

Page

30

of 64

Doc.-No.: VA049318-10-OM-EN-0319-64-2