P

RODUCT INFORMATION

3.5.5. Motor lubrication

The JDN high performance grease contained in

the motor allows for operation with oil-free com-

pressed air.

It works over an operating time of about 250 hours

and should, however, be replaced as required, but

after five years at the latest.

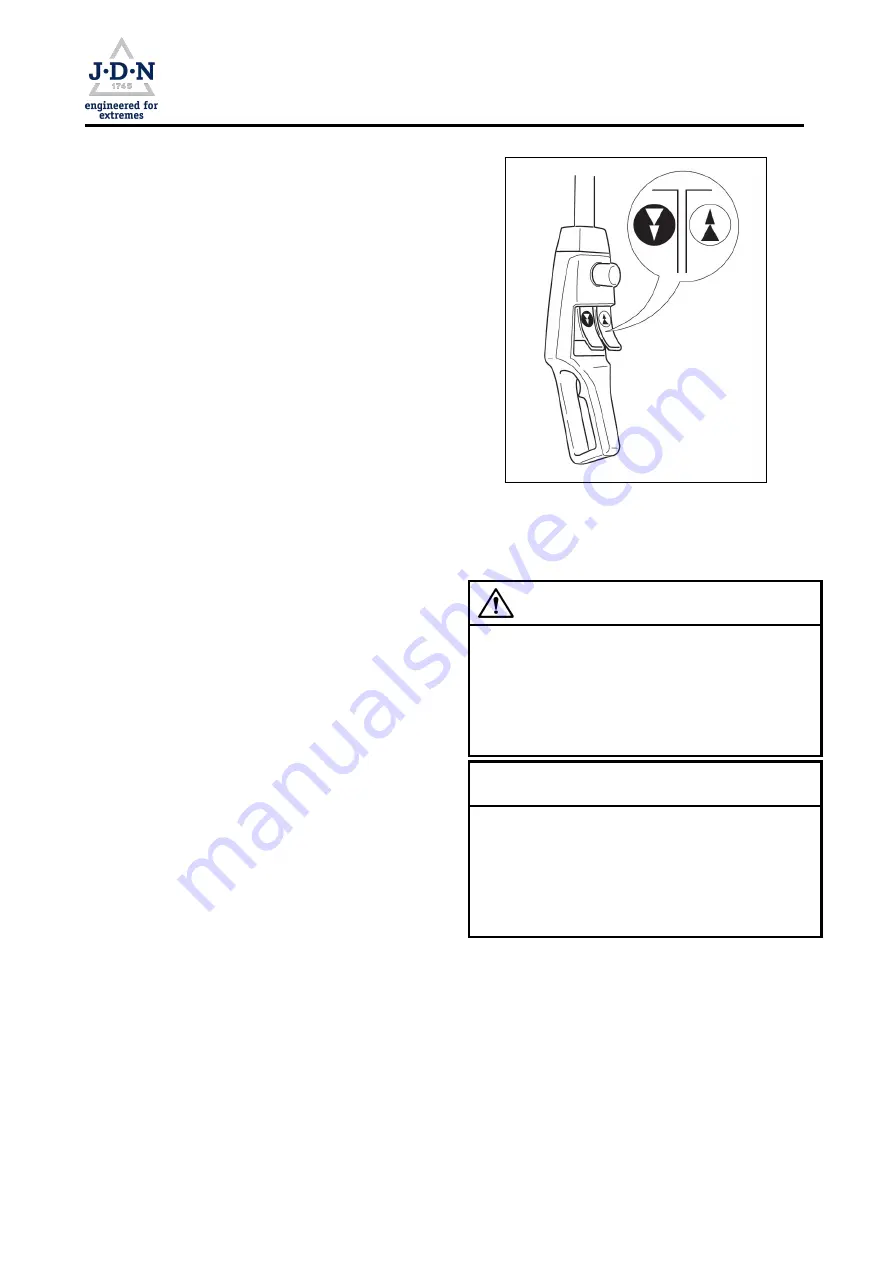

3.5.6. Control

With FI control (

,

→

Figure 5), the lifting and low-

ering motion can be regulated via two adjacent

push buttons. In the process, the control pressure

is continuously adjustable so that a sensitive po-

sitioning of the load is possible. The direction of

movement of the load hook is indicated by arrows

on the push buttons.

I

Lifting: Gently push down the right push but-

ton. The load will be lifted slowly.

I

Depress the push button further to increase

the lifting speed.

I

Ease up on the push button slightly to reduce

the lifting speed.

I

Lowering: Gently depress the left push button.

The load will be lowered slowly.

I

Depress the push button further to increase

the lowering speed.

I

Ease up on the push button slightly to reduce

the lowering speed.

The control system is suitable for use in explosive

areas.

All control switches automatically return to the

neutral position when released. All movements are

stopped instantaneously and the load is securely

held in its current position.

3.5.7. EMERGENCY STOP device

Your control system is equipped with an EMER-

GENCY STOP device.

By pressing the red EMERGENCY STOP button,

a separate blocking valve closes and your product

PROFI 3 TI

instantly comes to a halt and the load

is held securely in its current position. The control

system is now inoperable.

Figure 5: Control

3.5.8. Lifting limiter

WARNING

Danger from chain fracture

If the buffers are damaged, unacceptably high

loads may act on the chain when starting the

lifting limiter. The chain may break.

I

Do not use product

I

Have product repaired (replace buffer)

NOTICE

The lifting limiter may only be started in cases of

emergency. The operator must monitor the load

hook movement and stop the lifting movement in

due time. Striking the buffer against the housing

is to be avoided. This may result in damage to the

buffers.

Your product is equipped with a limiter that stops

the lifting movement (

,

→

Figure 6).

In order to achieve a limitation of the lifting move-

ment, a buffer

(1)

is mounted to the bottom block /

load sleeve. If the buffer is moderately deformed

in the boundary layer, the overload protection

switches the motor off.

Doc.-No.: VA053957-40-OM-EN-0720-60-2

Page

15

of 60