altered: 18.05.2017

additional manual

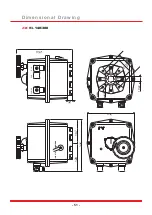

J3 C

+

J3C S

actuators

with Positioner (DPS)

technical changes reserved

Dat.: 10 08 14 0

compiled:

03.02.2017

Name:

AB

Additional instruction for

J+J

actuators

J3 S

+

J3C S

–Series with Positionier (DPS)

This instruction is additional to your

„ Basic instruction

J3 S

+

J3C S

“. For further technical details and advices

please mind those.

General:

The DPS electronic positioner converts the actuators into servo-controlled control device for valves. Using the input signal of the DPS,

it is possible to adjust to any pivoting range of the actuator. The DPS Module controlled by an integrated internal micro -processor

(CPU) the analog input-and output signal (4-20mA, 0-20mA or 0- 10V) and compared with the position of the actuator. For all

description, up from now you have to fill up the main safety rules for work at electric plants. For all you have to remove the handwheel

/ lever and the cover. After you have to close the cover and plug on the power and signal cable. Please take care to the cable route.

Don't wedge the cable with the cover.

The Input signal must be switched potential free (buffer amplifier)!

Technical Data:

Accuracy

3% *

Linearity

2% *

Hysteresis

3% *

Teilung

Min. 142 steps 90° 4/20mA

Min. 88 steps 90° 0/10V

Min. 166 steps 90° 0/20mA

Min. 85 steps 90° 1/10V

Min Auflösung /90°

1,30%

Class

B+C nach E DIN EN 15714 I Modulation

Input signal impedance

0-10V = 25KOhm / 4-20mA = 100Ohm

Weight

0,600 kg

Alignment of DPS positioner (

J3 S

+

J3C S

)

The „alignment of DPS positioner“ means to approach the configurated switch cams of the actuator, to set, or adjust the DPS limits.

This is necessary, every time when the swivel angle where changed. Please ensure, to only change in the configuration range of the

actuator (0°- 90°, 0°-

180°…). If the actuator is twisted out of this range, it will re-configurate itself after you put the power supply back

on. Because the system works potential-free, it maybe could be out of adjustment.