4

All dimensions in millimetres with inch equivalents in brackets.

Option 2: Toilet always above the heeled waterline

YOU MAY need A 19mm (3/4") non-return valve, Jabsco part

number 29295-1011

Run the inlet hose by the most direct route from the inlet

•

seacock to the flushing pump inlet tail.

For maximum convenience of use, install a 19mm (

•

3/4")

in-line non-return valve next to the inlet seacock, which

will ensure that the pump remains primed in between

usages.

5.3 Outlet Pipework - 4 options

Option 1: Toilet below the waterline and discharging

overboard. (See Figure 1 on Page 3)

YOU MUST fit a 38mm (11/2") Vented Loop fitting, Jabsco part

number 29015-0010.

Arrange the outlet hose to form a loop which is at least

•

20cm (8") above the highest possible waterline, and fit

the vented loop at the highest point.

Option 2: Toilet above the waterline, and discharging

overboard. (See Figure 2 on Page 3)

YOU MAY fit a 38mm (11/2") Vented Loop fitting, Jabsco part

number 29015-0010.

Run the outlet hose up from the discharge elbow to form

•

a loop at least 30cm (12") higher than the discharge

elbow.

If you fit a vented loop at the top of the hose loop this

•

will ensure that you can keep some water in the base of

the toilet without risk of it being siphoned away.

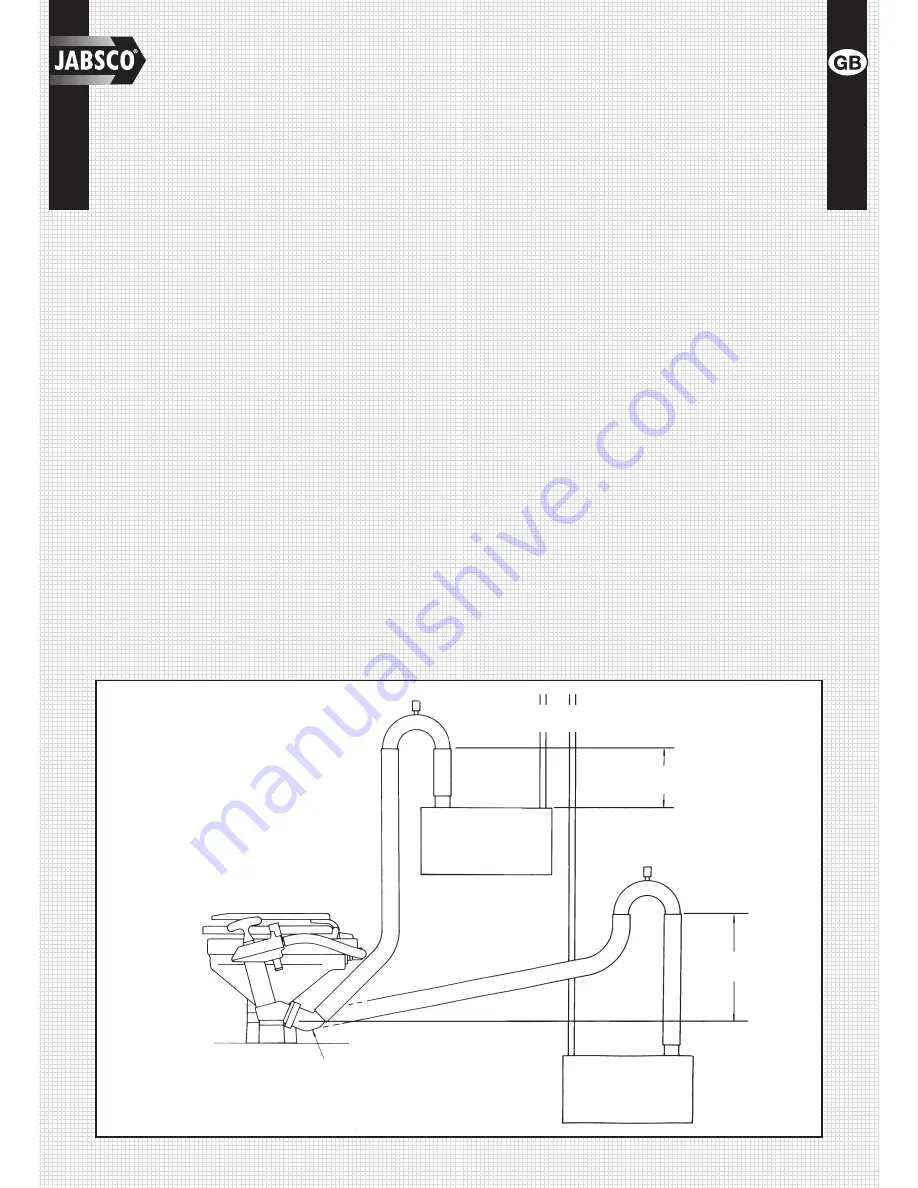

Option 3: Toilet waste discharging into holding tank, top of

holding tank above discharge elbow at anytime. (See Figure

3 below)

YOU MUST fit a 38mm (11/2") Vented loop fitting, Jabsco part

number 29015-0010.

•

If there is ANY possibility that the discharge elbow may

be below the top of the tank at ANY time, a ventilated

anti-syphon loop must be fitted in the outlet pipework to

ensure that the contents of the tank do not syphon out

through the bowl.

Arrange the outlet hose to form a loop which is at least

•

20 cm (8") above the highest possible level that the tank

may reach, and fit the Vented Loop at that highest point.

Option 4: Toilet waste discharging into holding tank,

discharge elbow always above top of holding tank. (See

Figure 3 below)

Run the outlet hose up from the discharge elbow to form

•

a loop at least 30cm (12") higher than the discharge

elbow.

This will create a water seal at the Joker Valve that will

•

prevent bad odours from escaping through the toilet.

YOU MAY fit a 38mm (11/2") Vented Loop fitting, Jabsco part

number 29015-0010.

•

If you fit a vented loop at the top of the hose loop this

will ensure that you can keep some water in the base of

the toilet without risk of it being siphoned away.

38mm (1 1/2")

VENTED LOOP

HOLDING TANK

VENT PIPES

AT LEAST

20cm (8")

OPTIONAL 38mm

(1 1/2") VENTED

LOOP

AT LEAST

30cm (12")

DISCHARGE

ELBOW

Option 3

Top of Holding Tank above

Discharge Elbow at any

time

Option 3

Holding Tank below

Discharge Elbow

Figure 3