5

5

11

10

9

8

17

12

13

14

15

16

18

19

20

21

22

23

25

FLUSH

FILL

DRAIN

4A

4B

1

2

3

24

5

6

7

4C

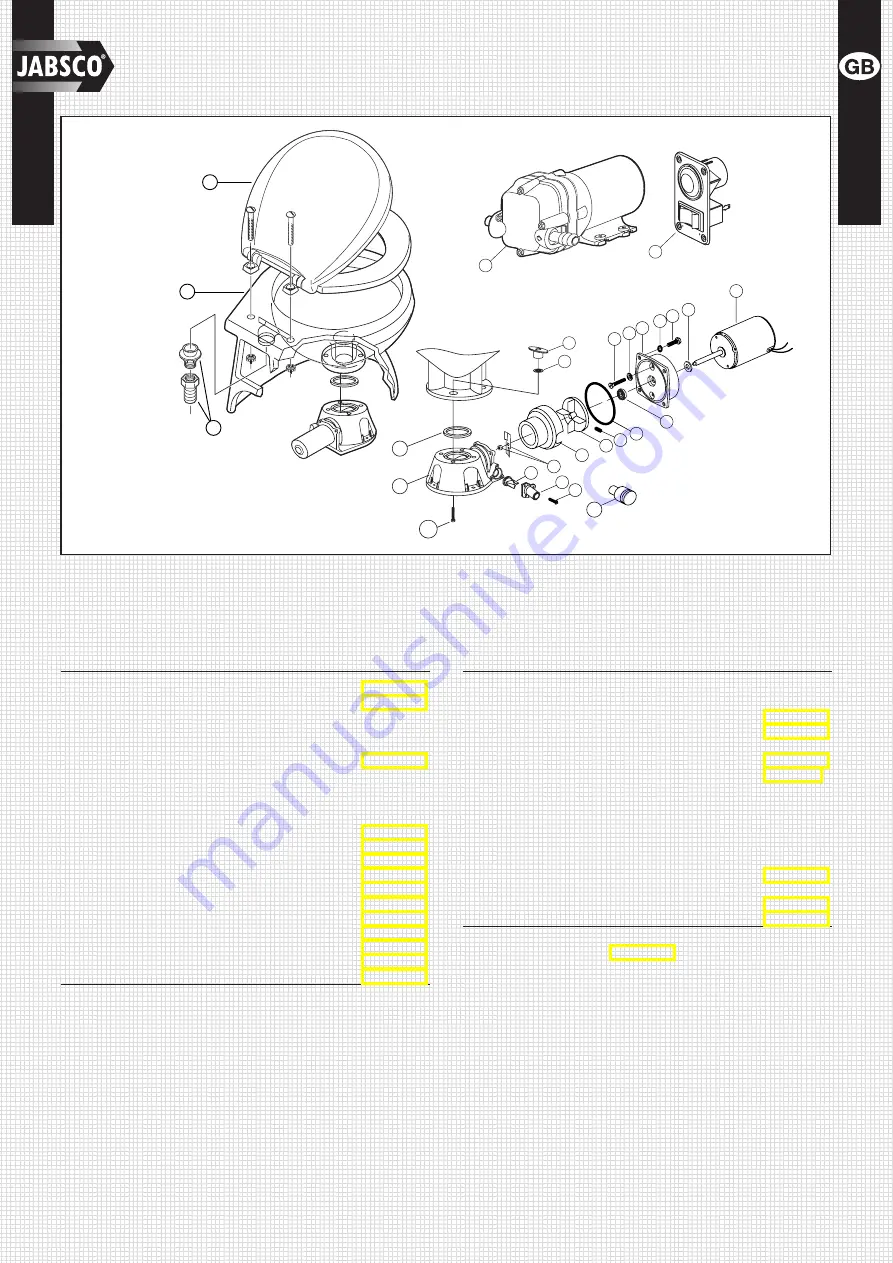

eXPloDeD VieW

Parts list

Qty.

Part

Key

Description

Req.

Number

1

Seat & Cover

1

2

Bowl, Compact Size, White

1

Bowl, Standard Size, White

1

37076-1010

Bowl, Compact Size, Bone

1

37076-2010

Bowl, Standard Size, Bone

1

37076-3010

3

Bowl Spud and 3/4

"

barbed adaptor

1

4

Bowl Installation Hardware

1

18753-0604

4A

Tee Nut**

4

4B

Washer, Plastic**

4

4C

Socket Head Screw**

4

5

Gasket*

1

6

Base Assembly**

1

7

1-1/2

"

Adaptor, Discharge Port

1

8

Joker Valve* **

1

9

1

"

Discharge Port**

1

10

Screw**

3

11

Chopper Plate with Lock Nut†

1

12

Macerator Housing †

1

13

Centrifugal Impeller†

1

14

Set Screw†

1

15

O-ring*†

1

Qty.

Part

Key

Description

Req.

Number

16

Seal†

1

1040-0000

17

Screw†

2

91010-0144

18

Washer, Plastic*†

2

19

Seal Housing†

1

20

Lock Washer #10, Stainless Steel†

4

21

Screw†

4

22

Slinger†

1

23

Motor - 12 Volt EMC†

1

18753-0582

Motor - 24 Volt EMC†

1

18753-0583

24

PAR-MAX 4 Rinse Water Pump

12 Volt EMC

1

30631-1092

24 Volt EMC

1

30631-1094

25

Switch Panel

1

37047-1000

Service Kit

1

Waste Pump Assembly

12 Volt EMC

1

24 Volt EMC

1

* Parts supplied with Service Kit.

** Parts included with base 37004-1000.

† Parts included in Waste Pump Assembly