6/7

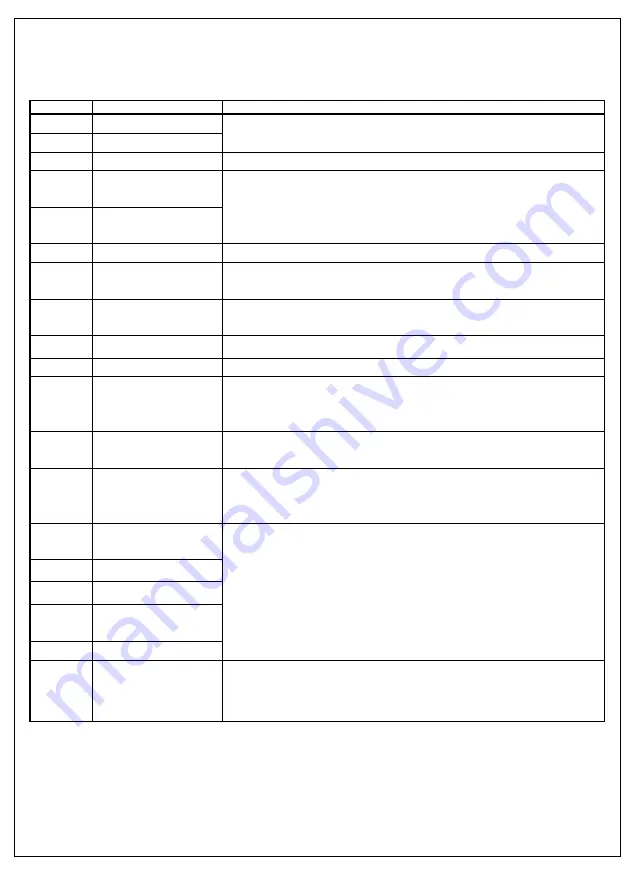

3.4 Error mode

If the error code appears, please check the following items first:

1.Make sure the machine has been connected correctly; 2. Reload the factory setting and try again.

Error Code

Description

Solution

E r r - 0 1

Hardware overcurrent

E r r - 0 2

Software overcurrent

Turn off the power switch, and restart after 30 seconds. If the controller still does not

work, please replace it and inform the manufacturer.

E r r - 0 3

Under-voltage

- Check mains voltage - Stabilize mains voltage

E r r - 0 4

Over-voltage when the

machine is off

E r r - 0 5

Over-voltage in operation

Disconnect the controller power and check if the input voltage is too high (higher than

264V). If yes, please restart the controller when the normal voltage is resumed. If the

controller still does not work when the voltage is at normal level, please replace the

controller and inform the manufacturer.

E r r - 0 6

Short circuit of solenoid

- Take plug out, if error continues, replace control box -

E r r - 0 7

Motor current measuring

failure

Turn off the system power, restart after 30 seconds to see if it works well. If such failure

happens frequently, seek technical support.

E r r - 0 8

Sewing motor blocked

- Eliminate sluggish movement in the sewing machine

- Replace encoder - Replace sewing motor

E r r - 0 9

Brake circuit failure

Check the brake resistor plug on the electric board. Replace the control box

E r r - 1 0

Communication failure

Check the connection and if necessary plug in. Replace the control box.

E r r - 1 1

Machine head needle

positioning failure

Check if the connection line between machine head synchronizer and controller is

loose or not, restore it and restart the system. If it still does not work, please replace the

controller and inform the manufacturer.

E r r - 1 2

Initial motor electrical angle

failure

- Try 2 to 3 more times after power down

- if it still does not work, please replace the controller and inform the manufacturer.

E r r - 1 3

Motor HALL failure

Turn off the system power, check if the motor sensor plug is loose or dropped off,

restore it and restart the system. If it still does not work, please replace the controller

and inform the manufacturer.

E r r - 1 4

DSP Read/Write EEPROM

failure

E r r - 1 5

Motor over-speed protection

E r r - 1 6

Motor reversion

E r r - 1 7

HMI Read/Write

EEPROM failure

E r r - 1 8

Motor overload

Turn off the system power, restart the system after 30 seconds, if it still does not work,

please replace the controller and inform the manufacturer.

E r r - 2 3

Sewing motor blocked

encoder failure

- Eliminate sluggish movement in the sewing machine

- Replace encoder - Replace sewing motor

Интернет магазин промышленного швейного оборудования http://procapitalist.ru/sms