STOP FOR SAFETY!

Safe assembly, operating and maintenance practices should always be

followed whenever using any equipment. Wherever you see the caution sign,

extra safety precautions should be taken.

You must stop, read, and carefully follow the safety instructions before proceeding.

READ THROUGH THE ENTIRE MANUAL

It is recommended to read through the entire manual before beginning your

installation and/or operating your furnace. Follow all steps exactly.

NFPA PRACTICES

Areas of this manual refer to the National Fire Protection

Association (NFPA). NFPA is a non-profit organization.

This furnace must be installed according to NFPA codes.

NFPA Codes, Standards, recommended practices, and guides referred to in this document are approved by

the American National Standards Institute. State and local codes are adopted from these standards.

DANGERS-CAUTION - FIRE HAZARDS

(BURN WOOD LOGS OR COAL ONLY)

Ducts and Plenums shall be constructed entirely of sheet metal

Do Not use flammable liquids to start a fire.

Do Not attempt to light a wood fire when gas or oil vapors are present.

Do Not install on a combustible floor.

In the event of an electrical power failure, be sure ash door and fire door remain closed.

Do Not install a power humidifier on warm air plenum.

Store all ashes in a metal container with a tight fitting lid. Allow ashes to cool before disposing of them.

Be sure there is a sufficient supply of outside combustion air to the area where the furnace is located.

Keep smoke pipe connection as short as possible with a minimum of 1-inch rise per linear foot from the

furnace to the chimney opening. Smoke pipe shall be 24 gauge galvanized or black pipe.

Before servicing, allow furnace to cool. Shut off electricity.

Familiarize yourself with this wood burning furnace before leaving it unattended.

Follow a regular service and maintenance schedule of furnace and chimney.

IN THE EVENT OF A CHIMNEY FIRE, CALL FIRE DEPARTMENT, AND THEN BE SURE ALL FURNACE

DOORS ARE CLOSED TIGHTLY. TURN OFF ELECTRIC POWER TO FURNACE.

Safety Statements

SAVE THESE INSTRUCTIONS

Safety Statements

4

Summary of Contents for BIG BJ90

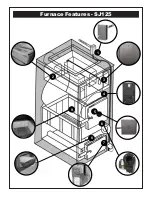

Page 11: ...3 1 2 4 5 6 7 8 9 Furnace Features SJ125...

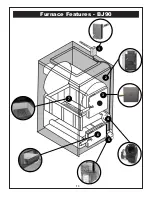

Page 13: ...1 2 3 4 5 6 7 Furnace Features BJ90 13...

Page 46: ...SUPER JACK SJ125 Exploded Views Parts Lists 46...

Page 48: ...BIG JACK BJ90 Exploded Views Parts Lists 48...

Page 53: ...Notes...

Page 54: ...Notes Notes...

Page 55: ...Notes...