7

Short press the short thread button

(

)

, you can select the fabric of the short thread. When you press

this button continuously, the pattern cycle is as follows: knitting mode K, woven mode W, large gauge mode L.

After setting up, press the P button

(

)

to confirm and save, and the 5S key-less does not save and return to

the standby interface.

When fabric selection is changed, the needle gauge U25 parameter is automatically associated with the

corresponding default value.

2.18

定期保养 Regular maintenance

当机器使用时间到达定期保养提醒时间后,面板会显示

A09/A10

,并语音播报提示,

10min

后再次播报提示且不再显示

A09/A10

直到下一个提醒时间到。可通过修改

PA0/PA1

的参数值设定提醒时间或关闭该提醒功能。

注:定期保养提醒过程中可正常缝纫。

When the machine use time arrives at the regular maintenance reminder time, the panel will display A09/A10,

and voice broadcast prompt, 10 minutes later again broadcast prompt and no longer display A09/A10 until the next

reminder time arrives. The alarm time can be set or the alarm function can be turned off by modifying the

parameter values of PA0/PA1.

Note: Normal sewing can be done during regular maintenance reminder.

2.19

短线头模式快捷开关 Short thread mode quick switch

长按短线头键(

)

3s

,进行短线头模式开关切换。

短线头模式开启时,第四传感器开关会自动关联开启,且会重新自动校准传感器电压值,

显示

OK

表示选择自动校准成功。

自动剪线补偿打开时,剪线快捷键中的前剪线延迟针数

P27

更改为出厂针距

U25

。

注意:短线头模式开启时,如果自动补偿针数无效,则自动关闭第四感应器。

Press the short thread button

(

)

for 3 seconds to switch the short thread mode.

When the short thread mode is turned on, the fourth sensor switch will be automatically turned on, and the

sensor voltage value will be automatically calibrated again. The OK indicates that the selection of automatic

calibration is successful.

When automatic trimming compensation is opened, the number of delayed needles in the front trimming line

P27 in the trimmer quick button is changed to the factory needle spacing U25.

Note: When the short thread

m

ode is turned on, if the number of automatic compensating needles is invalid,

the fourth sensor will be automatically turned off.

3

数码管显示说明 Digital tube display Instructions

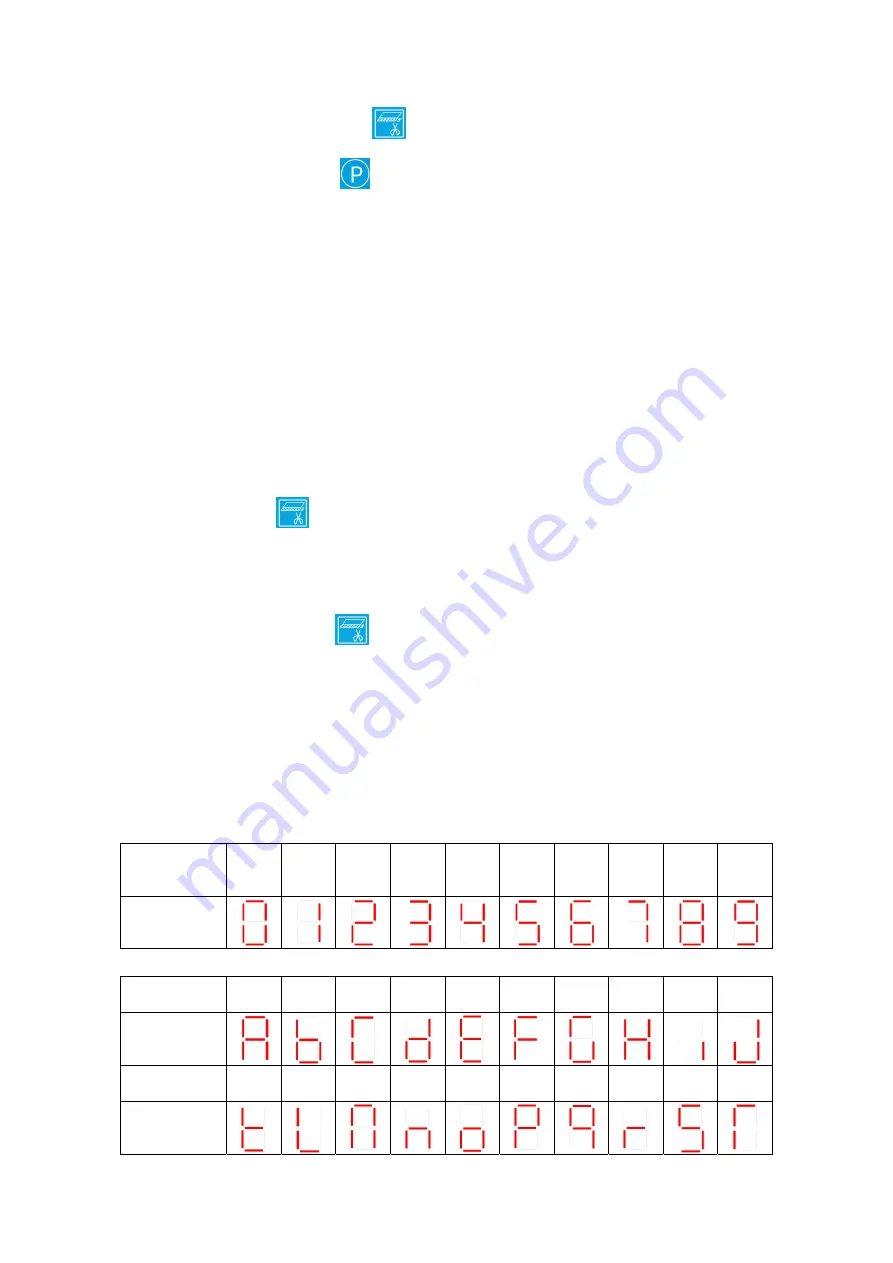

(1)数字部分: Digital section

实际数值

Actual

numerical value

0 1 2 3 4 5 6 7 8 9

数码管显示

Digital tube

display

(2)英文字母部分:English letter section

英文字母

English letter

A B C D E F G H I J

数码管显示

Digital tube

display

英文字母

English letter

K L M N O P Q R S T

数码管显示

Digital tube

display