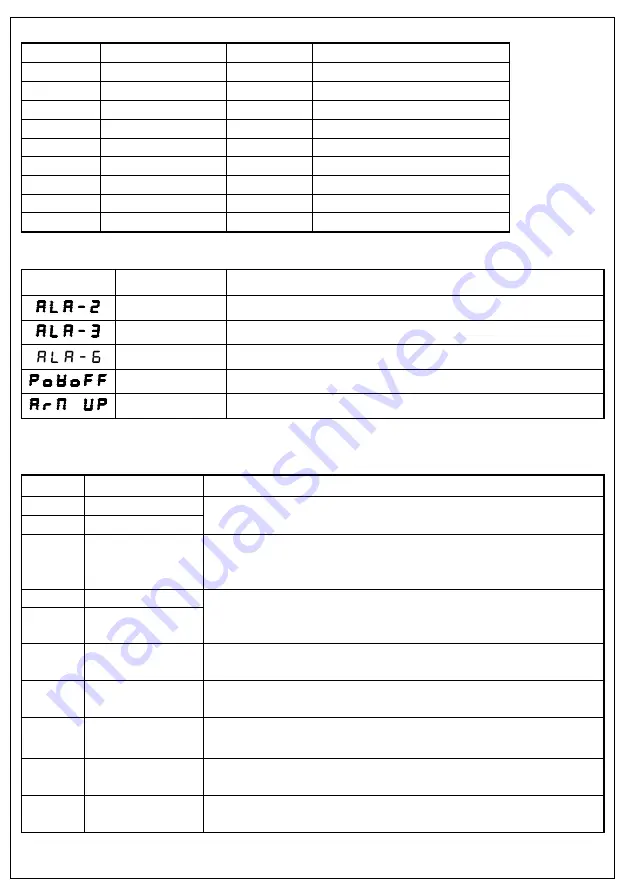

3.2 监控参数表

参数编号

参数描述

参数编号

参数描述

0 1 0

针数计数

0 2 5

踏板电压采样值

0 1 1

计件数

0 2 6

机头传动比实际值

0 1 2

机头实际速度

0 2 7

电机累计运行时间(Hour)

0 1 3

霍尔状态

0 2 8

机头交互量电压采样值

0 2 0

母线电压

0 2 9

DSP 软件版本号

0 2 1

机头速度

0 2 A

模拟输入 1 采样值

0 2 2

相电流

0 2 B

模拟输入 2 采样值

0 2 3

初始角度

0 2 C

错误计数器

0 2 4

机械角度

0 3 0 - 0 3 7

历史故障代码

3.3 安全报警表

报警代码

代码含义

解决措施

计针数报警

表示计针数已达所设上限,按 P 键可取消报警并重新计数

计剪线数报警

表示计剪线数已达所设上限,按 P 键可取消报警并重新计数

底线报警

表示底线即将用完,请更换底线.按 P 键可恢复

断电提醒

请等候 30 秒再重新打开电源开关

翻台开关报警

摆正机头,确保翻台开关复原

3.4 故障代码表

若系统出现报错或报警,请首先检查如下项:

1、先确认机器的连接线是否连接完好;2、确认电控和机头是否匹配;3、确认恢复出厂是否准确。

故障代码

代码含义

解决措施

E r r- 0 1

硬件过流

关闭系统电源,30 秒后重新接通电源,控制器若仍不能正常工作,请更换控制器并通知厂方。

E r r- 0 2

软件过流

E r r- 0 3

系统欠压

断开控制器电源,检查输入电源电压是否偏低(低于 176V)。若电源电压偏低,请在电压恢

复正常后重新启动控制器。若电压恢复正常后,启动控制器仍不能正常工作,请更换控制器

并通知厂方.

E r r- 0 4

停机时过压

断开控制器电源,检查输入电源电压是否偏高(高于 264V)。若电源电压偏高,请在电压恢

复正常后重新启动控制器。若电压恢复正常后,启动控制器仍不能正常工作,请更换控制器

并通知厂方

E r r- 0 5

运行时过压

E r r- 0 6

电磁铁

回路故障

关闭系统电源,检查电磁铁连线是否正确,是否有松动、破损等现象。若有则及时更换。确

认无误后重启系统,若仍不能工作,请更换控制器并通知厂方。

E r r- 0 7

电流检测

回路故障

关闭系统电源,30 秒后重新接通电源观察是否能正常工作。重试几次,若该故障频繁出现,

请更换控制器并通知厂方。

E r r- 0 8

电机堵转

断开控制器电源,检查电机电源输入插头是否脱落、松动、破损,是否有异物缠绕在机头上。

排除后重启系统仍不能正常工作,请更换控制器并通知厂方。

E r r- 0 9

制动回路故障

关闭系统电源,检查电源板上白色的制动电阻接头是否松动或脱落,将其插紧后重启系统。

若仍不能正常工作,请更换控制器并通知厂方。

E r r- 1 0

HMI 通讯故障

检查控制面板与控制器的连线是否脱落、松动、断裂,将其恢复正常后重启系统。若仍不能

正常工作,请更换控制器并通知厂方。

6

/

7

Summary of Contents for JK-58420B

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4...

Page 6: ...58420J 58420J Electronic Control Instructions...

Page 8: ...1 3 AC 2 2 1 2 1 2 2 1 12 2 13 W 14 15 16 17 18 2 7...

Page 23: ...2019 03 Edition 2019 March...