9/9

4 Pedal sensitivity adjustment

4 Pedal sensitivity adjustment

4 Pedal sensitivity adjustment

4 Pedal sensitivity adjustment

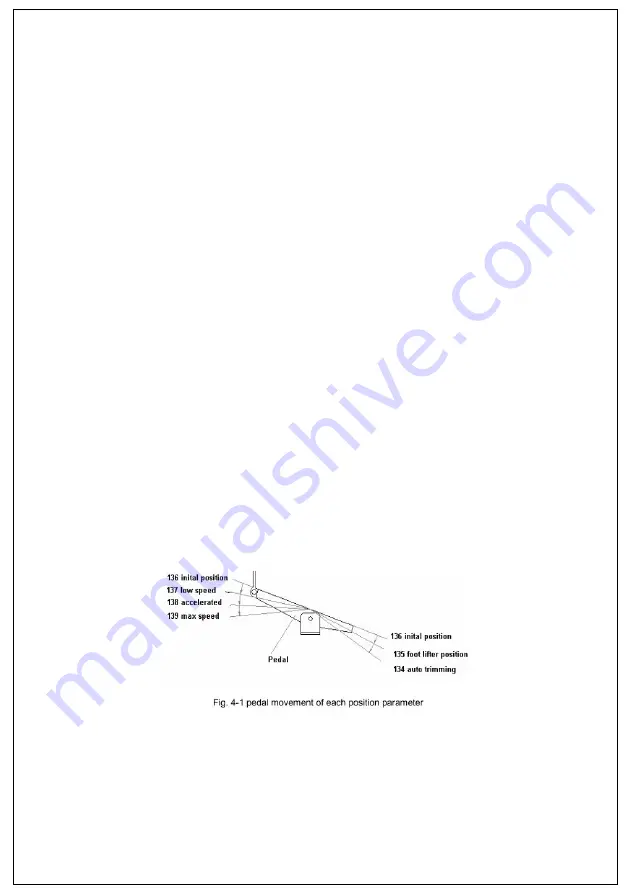

Pedal starts moving from the initial position ①(p.136) where the motor stops, slowing forward to the

low speed point② (p.137)

where the motor run as the minimum speed , continuing to the accelerated point (p.138) where the motor

start to speed up, until the max speed point (p.139) where the motor run up to the maximum speed. ②③ keep

start sewing speed, ③④ is free adjust process.

1; Pedal starts moving from the initial position ①(p.136), And when the pedal steps back to the foot lifter

position ⑤(p.135), the presser foot lift.

2: Pedal starts moving from the initial position ①(p.136),Continuing back to the auto trimming position

⑥ (p.134), the line is cut.

3. all the parameter should confirm( p.134) <(p.135)<(p.136)<(p.137)<(p.138)<(p.139)

4. It can be monitored in real time under the monitoring p.025 parameter, and the pedal sampling value

at different locations is the reference value of each parameter.

Adjusting the corresponding parameters, the action position of presser foot and front step or back step

is also changed. If the machine is not running before stepping on a large distance, the 137 parameter can

be reduced appropriately (Cannot less than parameter 136). It can improve the sensitivity of the front step;

if the machine is too sensitive, the light touch pedal machine starts to run, and the 137 parameters can

be increased properly; if it is not easy to fill the needle and step forward slightly,

The speed increases rapidly to lead multiple needles, which can be properly increased by 138 parameters or

reduced by 137 parameters (that is to increase the low speed range of the foot pedal), and the initial slit

speed (100) can be properly reduced.

Summary of Contents for JK-58420B

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4...

Page 6: ...58420J 58420J Electronic Control Instructions...

Page 8: ...1 3 AC 2 2 1 2 1 2 2 1 12 2 13 W 14 15 16 17 18 2 7...

Page 23: ...2019 03 Edition 2019 March...