⑧

剪线后抬压脚

⑲

拐角

⑨

抬压脚

○

20

油量检测

⑩

软启动功能

感应自动抬压脚

○

11

前加固缝

8 8 8 8 8 8 8 8

计数/参数值显示

2.2

操作面板各按键功能说明

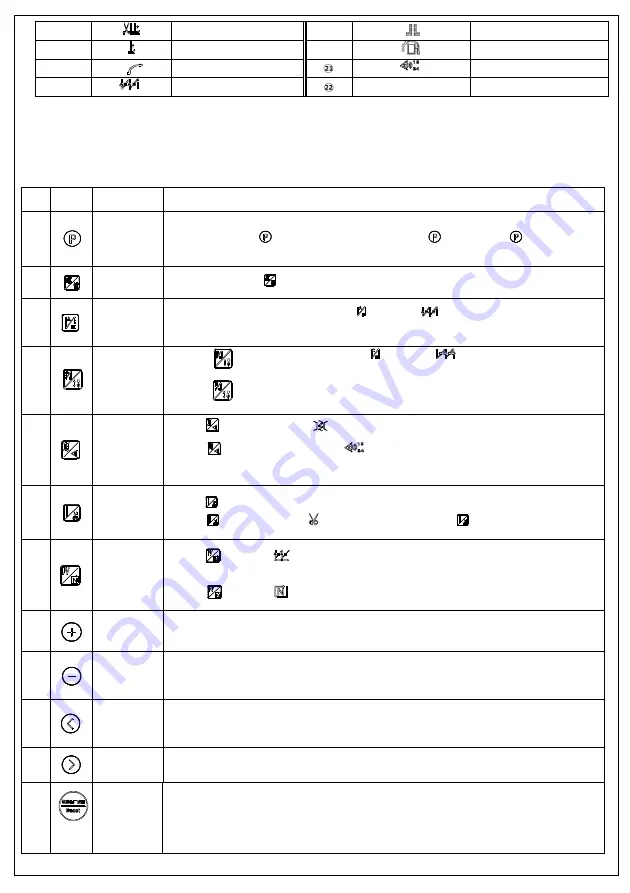

序号 外观

名称

功能描述

1

参数进入

及返回键

在开机状态下,长按

键进入参数模式。修改参数后按一下

键储存,再长按

键退出参数模式。

2

抬压脚键

在正常缝纫模式下,按

键,循环切换缝纫中途停车时抬压脚与缝纫结束后自动切线抬压脚。

3

前加缝键

前固缝选择键,每短按动一次,设置前固缝

、前双固缝

、关闭之间循环选择,对应液晶屏图

标点亮。选择对应的键可设置 A、B 段的针数,默认针数范围 0~F 对应 0~15 针。

4

后加固缝及

停针位键

1、短按 键,每短按动一次,设置后固缝

;后双固缝

;后固缝关闭之间循环选择,对

应液晶屏图标点亮。选择对应的键可设置 C、D 段的针数,默认针数范围 0~F 对应 0~15 针。

2、长按 键,设置上停针位、下停针位。

5

夹线键及压

脚感应器键

1、短按

键,液晶屏夹线图标

亮,夹线功能开启,再短按一次,夹线功能关闭。

2、长按

键,液晶屏压脚感应器图标

亮,打开压脚感应器功能,再长按一次,压脚感应器

功能关闭。

6

自由

缝及剪线键

1、短按

键,选择自由缝模式。

2、长按

键,液晶屏剪线图标

亮,自动剪线功能开启,再长按

键,自动剪线功能关闭。

7

W 缝/多段缝

键

1、短按

键,液晶屏

图标

亮

,表示当前是 W 缝模式。

2、长按

键,液晶屏

图标亮,表示当前是多段缝模式。

8

参数递增键

参数设定中,参数值递增键。

9

参数递减键

参数设定中,参数值递减键。

10

向左选择键

参数设定中,向左选择参数范围。(在多段缝模式下,长按该键,触发指示灯点亮,即触发模式开启;

再长按该键,触发指示灯熄灭,触发功能关闭)

11

向右选择键

参数设定中,向右选择参数范围。

12

恢 复 出 厂 设

置

长按 5s 恢复出厂设置。

3

/

7

Summary of Contents for JK-58420B

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4...

Page 6: ...58420J 58420J Electronic Control Instructions...

Page 8: ...1 3 AC 2 2 1 2 1 2 2 1 12 2 13 W 14 15 16 17 18 2 7...

Page 23: ...2019 03 Edition 2019 March...