1

2

3

58420J 电控使用说明书

第 1 章 产品安装

1.1 产品规格

产品型号

AHE59

电源电压

AC 220±20% V

电源频率

50Hz/60H

z

最大输出功率

750W

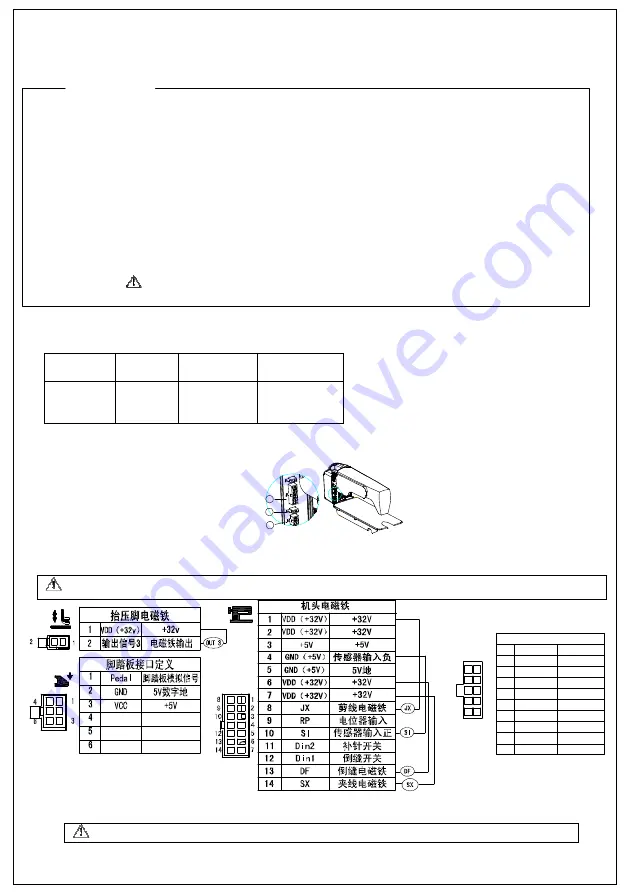

1.2 接口插头的连接

将脚踏板及机头的各连接插头安插到控制器后面对应的插座上,各插座名称如图 1-2 所示。连接好,请检查插头是否插牢。

图 1-1 AHE 系列控制器图

①

踏板插座;②抬压脚电磁铁插座;③自动电磁铁插座;

图 1-2 控制器接口定义

:

使用正常的力量插不进去时,请检查插头与插座是否匹配,插入方向或针的方向是否正确!

:

所有电源线、信号线、接地线等接线时不要被其它物体压到或过度扭曲,以确保使用安全!

·

在使用本产品之前,请先阅读《操作手册》及所搭配的缝纫机机械说明书。

·

本产品必须由接受过专业培训的人员来安装或操作。

·

请尽量远离电弧焊接设备,以免产生的电磁波干扰本控制器而发生误动作。

·

请不要在室温 45℃以上或者 0℃以下的场所使用。

·

请不要在湿度 30%以下或者 95%以上或者有露水和酸雾的场所使用。

·

安装控制箱及其他部件时,请先关闭电源并拔掉电源插头。

·

为防止干扰或漏电事故,请做好接地工程,电源线的接地线必须牢固的方式与大地有效连接。

·

所有维修用的零部件,须由本公司提供或认可,方可使用。

·

在进行任何保养维修动作前,必须关闭电源并拔掉电源插头。控制箱里有高压危险,必须关闭电源五分钟后

方可打开控制箱。

·

本手册中标有

符号之处为安全注意点,必须注意并严格遵守,以免造成不必要的损害。

安全事项

DIN5

1

10

6

5

1

DIN6

+5V

OUT6

OUT7

GND32V

GND32V

GND32V

电磁铁2

VDD

VDD

2

3

4

5

6

7

8

9

10

输入5

输入6

+5V

输出6

输出7

地

地

地

32V

32V

1

/

7

Summary of Contents for JK-58420J

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4...

Page 6: ...58420J 58420J Electronic Control Instructions...

Page 8: ...1 3 AC 2 2 1 2 1 2 2 1 12 2 13 W 14 15 16 17 18 2 7...

Page 23: ...2019 03 Edition 2019 March...