5/8

P 1 7

0~99 0

Automatic induction presser foot sensor setting (between the maximum and minimum

value of the 02C parameter display)

P 2 4

0~1024

150

Trimming point of pedal

P 2 7

0~3

1

Presser Foot sensor mode setting: 0: off 1: turn on only after trimming 2: always ON

P 3 0

0~31 0

Feedforward torque of motor: 0: normal functions 1-31: feedforward torque level

P 3 2

1~500 60

Encryption seam solenoid full open time (ms)

P 3 3

0~100 6

Encryption seam solenoid off time per cycle (ms)

P 3 7

0~100

5

Encryption seam solenoid on time per cycle (ms), means the clamp strength.

P 3 8

1~999

120

Flat seaming shear velocity (under the knife to maintain time) -- -- -- -- -- - under the knife

P 3 9

1~999

160

Scavenging action time delay -- -- -- -- -- -- -- -- -- -- on the knife (note: this is also flat

seaming machine cut line)

P 4 0

1~999

30

Duration and linear velocity (scan line) -- -- -- -- -- -- -- -- on the knife (note: this is also flat

seaming machine cut line)

P 4 1

0~9999

120

Blowing began to delay time(ms)

P 4 2

1~9999

300

Blowing duration(ms)

P 4 3

0~25

2

Sweep line, choice of blowing function (2 for scavenging; 8 for blowing)

P 4 5

0~100

1

Trimming electromagnet per cycle opening time (ms)

P 4 6

0~100

2

Trimming electromagnet per cycle closing time (ms)

P 4 9

100~500

300

Trimming Speed

P 5 0

1~500 100

Presser foot lifting electromagnet full output time ms

P 5 1

0~100

15

Presser foot lifting electromagnet per cycle opening time (ms)

P 5 2

1~800 150

Running delay time when presser footer comes down (ms)

P 5 3

0/1 1

Presser foot lifting function selection

0: off 1: on

P 5 4

0~100

35

Presser foot lifting electromagnet per cycle closing time (ms)

P 5 6

0/1 1

Run to up needle position after Power on

喚

0: no action 1: action

P 5 7

0~600 200

Presser foot lifting electromagnet protection time 100ms

P 6 0

200~5500 4000

The maximum speed of constant sewing (Automatic test speed)

P 6 2

0~4 0

Special mode:

0: normal Mode

1: simply sewing mode

2: motor initial angle measurement (Do not remove the belt)

3: Automatically setting the pulley ratio by the CPU. (Synchronizer is necessary and the

belt not removed)

4:

automatic test modle 1 (It has needle stop position of automatic test, running and

stopping 5S)

P 6 6

0/2 2

Safety switch function set: 0:off 2:on

P 7 1

0~50

0

Slow release lifter level adjustment, the smaller values and the faster quickly (OC open

Summary of Contents for JK-K4-UT

Page 1: ......

Page 2: ...0 51 1 1 YKXOKY YK SGT GR...

Page 22: ...20 51...

Page 36: ...34 51 YKZ YIXK IXGTQ JOYQ JXO K IUTTKIZOTM XUJ T Z T Z...

Page 40: ...38 51 Moving cutter is parallel to the fixed cutter Screw1 Screw3 Screw4 Screw2 Fixed cutter...

Page 41: ...39 51 JP YZ IROV GTJ VXKYY XK YNKKZ clip Pressure sheet clip is parallel to the fixed cutter...

Page 47: ...45 51...

Page 48: ...46 51 SS...

Page 50: ...48 51...

Page 52: ...50 51...

Page 53: ...f 9 g g g g g g g g g g...

Page 54: ...1 11 2 12 13 14 15 16 17 8 8 8 8 8 8 8 8...

Page 55: ...3S...

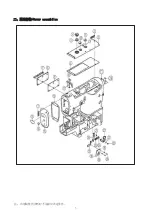

Page 68: ...XVKLQJ DVVHPEOLHV...

Page 70: ...UDPH DVVHPEOLHV...

Page 72: ...RYHU DVVHPEOLHV...

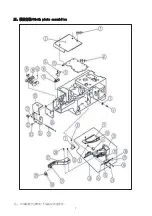

Page 74: ...ORWK SODWH DVVHPEOLHV...

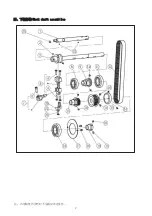

Page 76: ...RRN VKDIW DVVHPEOLHV...

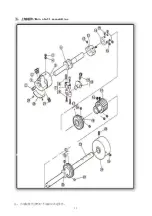

Page 78: ...0DLQ VKDIW DVVHVPEOLHV...

Page 80: ...1HHGOH EDU DVVHPEOLHV...

Page 82: ...1HHGOH JXDUG DVVHPEOLHV...

Page 84: ...HHG PHFKDQLVP...

Page 86: ...1HHG PHFKDQLVP...

Page 88: ...3UHVVHU IRUP DVVHPEOLHV...

Page 90: ...1HHGOH IHHGLQJ DVVHPEOLHV...

Page 92: ...7KUHDG ORRVLQJ DVVHPEOLHV RQH...

Page 94: ...7KUHDG ORRVLQJ DVVHPEOLHV WZR...

Page 96: ...7KUHDG ORRVLQJ DVVHPEOLHV...

Page 98: ...DP DVVHVEOLHV...

Page 100: ...XEULFDWULRQ DVVHPEOLHV...

Page 102: ...2LO SXPS DVVHPEOLHV...

Page 104: ...6LOLFRQ RLO GHOLFH DVVHPEOLHV...

Page 106: ...DXJH VHW VSHFLILF SDUWV...

Page 108: ...QLIH KROGHU DVVHPEOLHV...

Page 111: ...7RS ZLSHU DVVHPEOLHV...

Page 113: ...6ROHQRLG DVVHPEOLHV...

Page 115: ...OHFWURQLF FRQWURO DVVHPEOLHV...

Page 117: ...IWHU FDP DVVHPEOLHV...

Page 120: ...IWHU ILJKW FDP DVVHPEOLHV...

Page 122: ...7KUHDG SRRO VVHPEOLHV...

Page 124: ...35AC 35ACFT device...

Page 126: ...35AC 35ACFT device...

Page 128: ...FFHVVRULHV DVVHPEOLHV...

Page 130: ...HGSODWH DVVHPEOLHV...