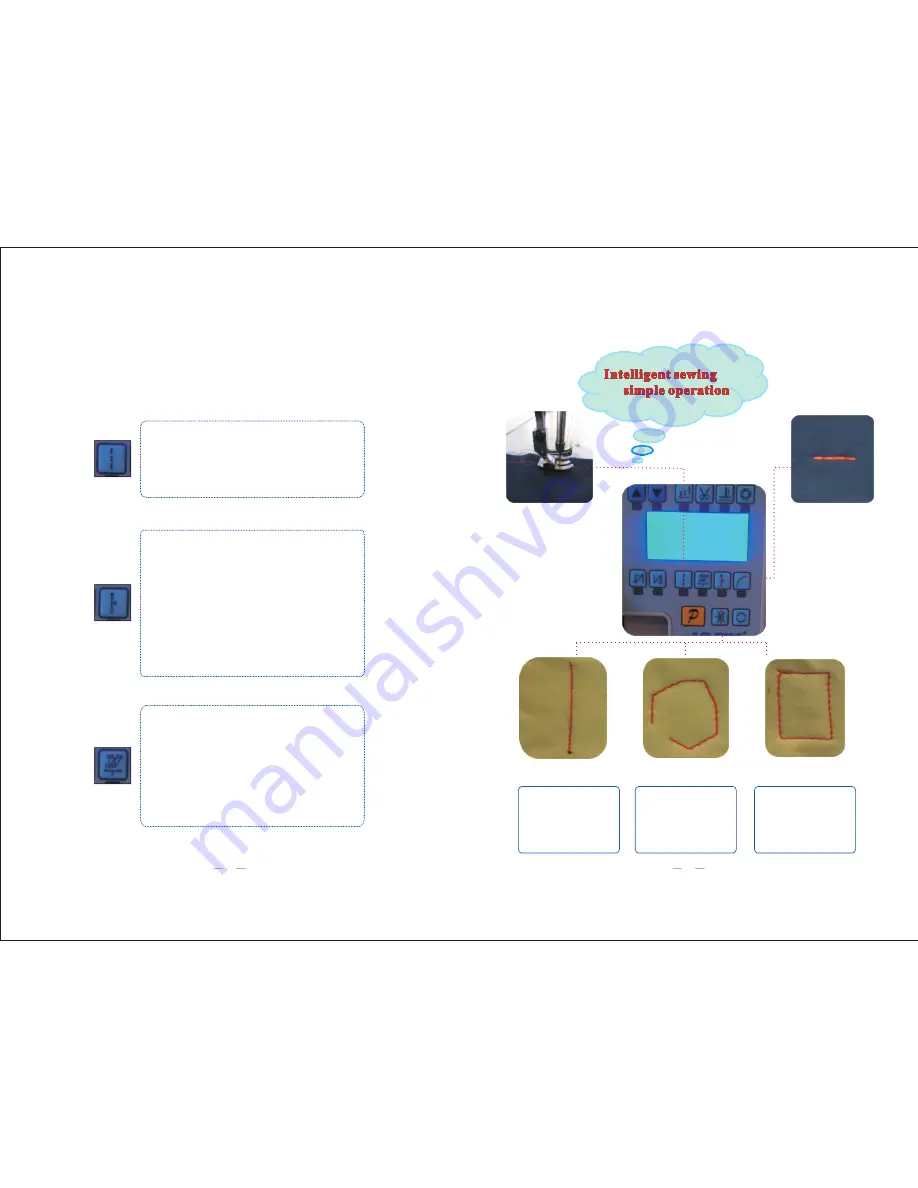

Press this key, the machine enters into “free sewing

mode”, the sewing length can be controlled by the

operator, that is why we called this function as“free

sewing model”. It’s often used for lap seam and bar-

tacking sewing.

Press this key, the machine enters into “fixed-stitch

sewing mode”, the sewing length and segment is

confirmed by the operator through control panel, and

sewing will be finished automatically. The operator

only needs to pedal the speed controller, then will

work automatically till finishing the trimming. It’s

often used for sewing the fixed-length thread

segment and the trademark.

Press this key, the machine enters into “W pattern

bar-tacking sewing mode”, the bar-tacking stitches

and times are set up by the operator through control

panel, and sewing will be finished automatically. The

operator only needs to pedal the speed controller,

then machine will work automatically till finishing

the trimming. It’s often used for straight bar-tacking

sewing.

Intelligent sewing

simple operation

Intelligent sewing

simple operation

You can set the stitch

length according to

customer’s requirement

,after sewing ,it will auto

trimmer and auto stop .

You can set edges number

and stitch numbers of each

edge according to

customer’s requirement

,after sewing ,it will auto

trimmer and auto stop .

Common Fixed-stitch

length sewing model:

It is used to sewing

rectangular lables.

Fixed-stitch length

sewing model 2:

Fixed-stitch length

sewing model 1:

Selection of Sewing Mode

6

7

Summary of Contents for JK-SHIRLEYIIE

Page 18: ...MEMO MEMO...