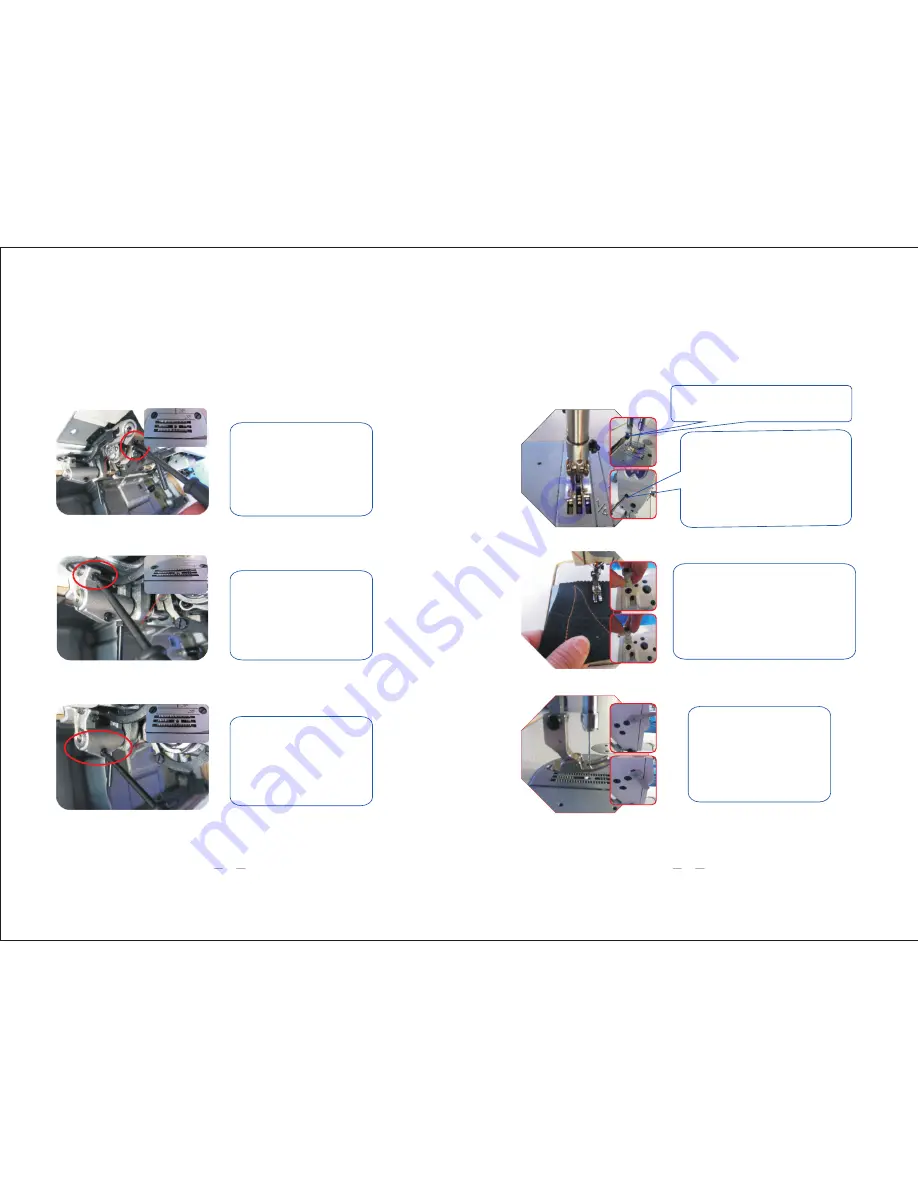

Adjustment of feed dog

Height adjustment for feed dog

Unscrew the braces screw

For light fabric, appropriately

adjust feed dog lower

For heavy fabric, appropriately

adjust feed dog higher .After

finishing ,tighten the screws.

Adjustment for feed dog gradient

Unscrew the screw,turn the brace

and adjust the eccentric shaft, it can

adjust teeth front or back,high or

low.This step depend on different

fabric.

Front or back for feed dog

Adjust the needle spacing to

maximum, unscrew the braces screw,

and it can adjust feed dog front and

back, when the machine is running,

please pay attention to the teeth

front and back and can not touch the

throat plate ,and feed dog left and

right also can can not have the

friction with needle plate.

Change the presser footer:

loose the footer screw then can change

the presser footer.

Adjust the footer and needle:

When the needle is not in the middle of the

presser footer ,or the feed dog is in low

position. Unscrew and adjust the presser to

the right position . Then tighten it.

Adjusting the pressure of

the presser footer:

Lifting the footer, put the fabric below the footer,

put down the footer, pull the fabric by hand, if

the fabric can be easily pull out, so need increase

the pressure of the footer. Loose the press rod

nut, rotate it in the clockwise direction, if you

want to reduce the pressure, please rotate it in the

anticlockwise direction.

Footer protect:

When the machine work without

fabric, must move up the presser

footer protection wrench, lift the

footer, can reduce the ware rate of

the teeth and presser footer.

Adjustment of the presser foot lifter

12

13

Summary of Contents for JK-SHIRLEYIIE

Page 18: ...MEMO MEMO...