16

BEFORE OPERATING YOUR LOCKSTITH MAC

H

INE, PLEASE READ THIS

INDTRUCTION MANUAL CAREFULLY IN ORDER TO OPERATE IT IN THE

CORREC

T

AND EFFICIENT MANNERS.

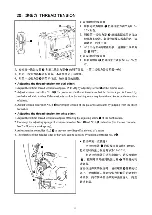

运行中警告

CAUTIONS IN OPERATION

1.

机器从滑轮的正面观察

应

该逆时针方向旋转,注意不要让缝纫机反方向旋转

。

2.

在没有加油之前,不允许开动机器

。

3

.

在试运行前,请从机器中拿出线轴箱和针线

。

4

.

每天在缝

工

作之后应及时清理缝钩和机器线轴,另外应经常检查缝纫机油的油

量

。

5.

为防止人身事故的发

生

,缝纫机在运行戒电机在转动过程中,请不要将

手

指、头发、衣

服

等靠

近

手

轮,也不要把任何东西放到机器上

。

6.

如果你的机器配有封带

,

为了保护你的

手

指和和眼睛,在进行操作前

,请

将它

们

除去

。

1. The machine should rotate counterclockwise as observed from the pulley. Take care

not to rotate the machine in the opposite direction.

2. Never start the machine before filling the machine base with lubricating oil.

3. Remove the bobbin case and the needle thread from the machine before performing

the trial operation.

4. Clean up the sewing hook and the bobbin thread trimmer every day after sewing work.

Also check the level of the lubricating oil.

5. Never bring your fingers or hair close to, or place anything on the hand wheel during

operation. It may lead to serious peraonal injuries.

6. lf your machine is provided with a belt cover, finger guard and eye guard, never operate

your machine with any of them removed.

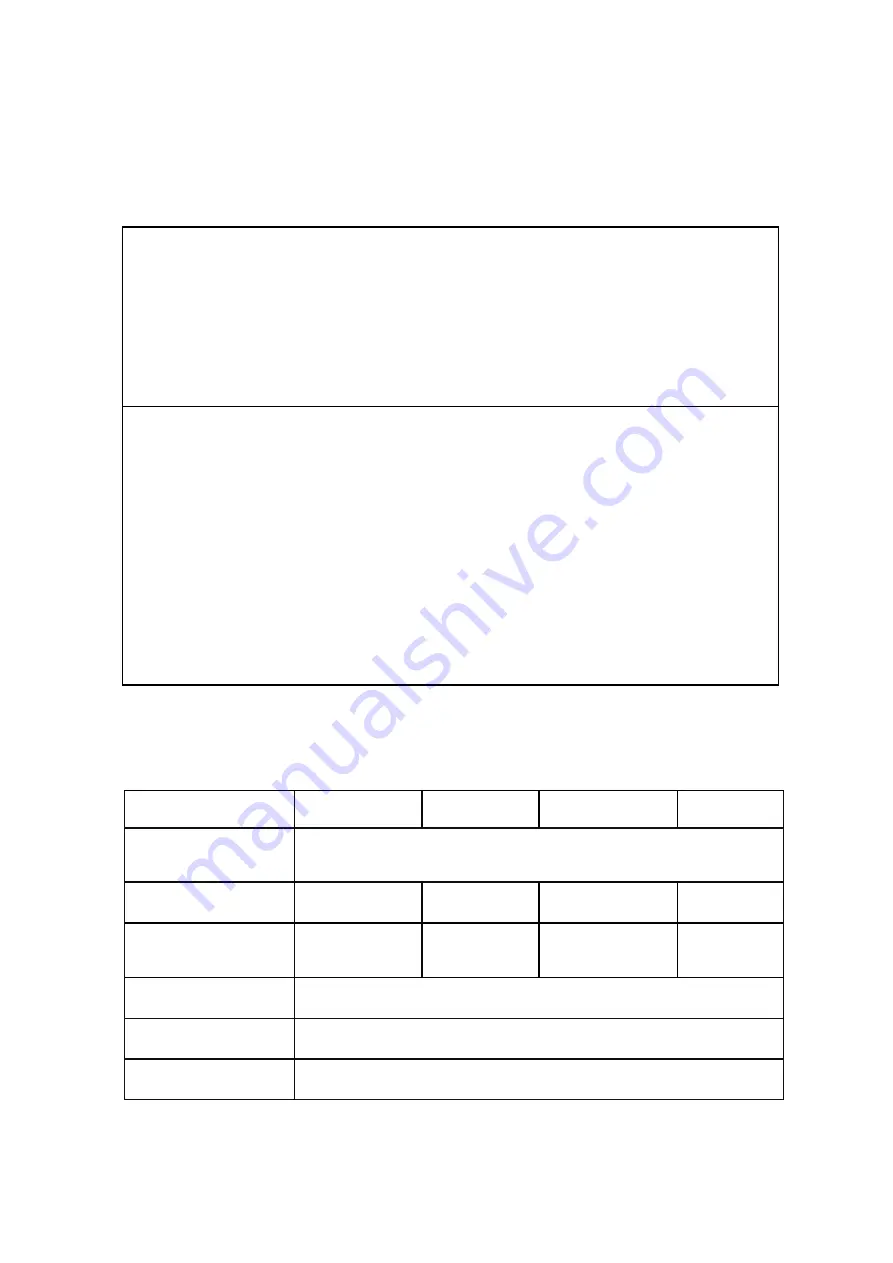

6:

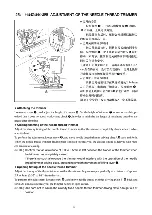

规格

SPECIFICATION

型

号

781E

782E

783E

781EK

用

途

Application

一

般布料,针

织

布料

等

的锁眼机

Buttonholin

g

fo

r

ordinar

y cl

oth

,

knit

,

e

tc

锁眼宽

度

Buttonhole length

2

.

5-4mm

2.5-5mm

2. 5-5m

m

2.5-4

mm

切刀长度

Bar-tack

width

6

.

4

-

19mm

( 1/4

"-

3

/

4")

6

.

4

-

25.

4mm

(1

/

4"-1"

)

6

.

4

-

31.75

mm

(1

/

4" 1 -

1

1/

4")

6

.

4

-

19

m

m

(

1

/

4"

-3

/

4

"

)

机

针

N

ee

dl

e

DPX5

#11J

-

#14J

压脚

高

度

Presser lift

12mm

使用机油

Lubricating oil

NO.

1

新机油

Summary of Contents for JK-T718E

Page 1: ......

Page 20: ......

Page 23: ...17...

Page 26: ...20...

Page 34: ...28...

Page 37: ...76...

Page 39: ...2 MAIN SHAFT COMPONENTS 30 30 3 24 13 45 3...

Page 41: ......

Page 43: ......

Page 45: ...5 NEEDLE BAR FRAME COMPONENTS 16 ss C 9...

Page 47: ...6 OVEREDGING WIDTH ADJUSTING COMPONENTS 5 43 45 11...

Page 51: ...8 BOBBIN THREAD TRIMMER COMPONENTS 1 35 39 40 20 18 21 21 1 15...

Page 53: ...9 KNIFE BAR COMPONENTS 9 13 54 55 56 59 1_1 64 65 ___66 63 33 17...

Page 54: ...18 P01011...

Page 55: ...10 FEED CAM TRIPPING SEGMENT COMPONENTS 47 1 Q 17 12 25 6 6 50 19...

Page 57: ...11 CONTROL BOX COMPONENTS...

Page 59: ...12 SAFE PROTECTION COMPONENTS...

Page 61: ...25...