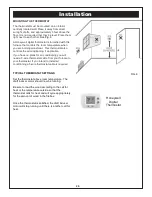

TO FUNCTION PROPERLY AND SAFELY

, it is impera-

tive that the draft regulator when installed in the Tee

stub, is pointing away from surrounding walls or obstruc-

tions. (See Fig. 12) Placement of draft regulator pointing

toward nearby wall(s) or obstruction(s) could result in a

hot spot on the exposed surface and subsequent fire

hazard.

REGARDLESS OF LOCATION AND POSITION

, the

Tee stub opening MUST be plumb (perpendicular) for

the draft regulator to function properly.

AFTER THE TEE SECTION LOCATION HAS BEEN

DETERMINED

, secure the section with both ends to

adjacent sections of standard smoke pipe. Three sheet

metal screws placed at equal distance around each end

of pipe will hold it firmly in place.

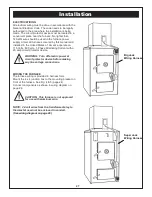

INITIAL SETTING OF BAROMETRIC DRAFT

REGULATOR

Before adjusting the draft regulator, be sure there is a

good fire burning.

Set the regulator at a maximum of -.03 to -.04 or as low

a draft as will give good combustion and meet the

requirements for heat. Turn adjustment weight counter-

clockwise to loosen, then slide in slot to proper position

and tighten. Bracket is marked 2, 4, 6, and 8, which

indicates draft settings of .02, .04, etc. (These are drafts

in flue adjacent to control, not over-fire drafts.)

A manometer must be used to accurately adjust flue

draft.

SETTING THE BAROMETRIC DRAFT REGULATOR AND SOME INFORMATION ON CREOSOTE

CREOSOTE BUILD UP

- Creosote, in a vaporized state,

is present in the gases emitted by burning wood and is

highly combustible in its solid and semi-liquid states.

Creosote may build up on the interior surface of the

chimney and subsequently reduce the draft opening. A

DANGEROUS CHIMNEY FIRE MAY RESULT IF ANY

APPRECIABLE CREOSOTE BUILD UP IS PERMIT-

TED.

ADVERSE CONDITIONS CONDUCIVE TO CREO-

SOTE BUILD UP

- Creosote condenses from the flue

gases more rapidly when the temperature in the chim-

ney is cool. The amount of creosote build up is

dependent on:

Ÿ

The amount of moisture in the flue gases

Ÿ

The temperature of the stack

Ÿ

The rate at which the wood is burned

Ÿ

The amount of draft in the stack

Ÿ

How completely the combustible elements in the

flue gases have been burned in the combustion

chamber

Most problems with creosote are due to insufficiently dry

or cured wood, inadequate chimneys with low draft and

cold walls (below 250°F), and/or too low a rate of burn-

ing when little heat is required during spring and fall

months.

CONTROL OF CREOSOTE

- Moisture in the flue

gases may be controlled by:

Ÿ

Using properly seasoned fire wood

Ÿ

Mixing small pieces of air dried wood with every

load

Ÿ

Never using only large wood (usually less dry)

during mild weather when combustion is relatively

slow

The temperature in the stack may be controlled by:

Ÿ

Using as short a length of stove pipe as possible

between the appliance and the chimney

Ÿ

Using an insulated (double wall) smoke pipe to

connect the appliance to the chimney

The amount of draft in the stack may be improved by:

Ÿ

Having as few bends as possible

Ÿ

Insuring adequate chimney height and preventing

air leaks

Ÿ

Eliminating external obstructions in the chimney

outlet

Ÿ

Having only one appliance per flue (Code)

REMOVAL OF CREOSOTE

- Accumulations of

creosote in smoke pipe and chimney flue should be

removed on a regular basis by dismantling and scraping

connector pipes and by scraping and brushing flue until

free of deposits. In many areas there are professional

chimney cleaning services available to perform this

cleaning operation.

FIG. 12

Installation

33

Tee Stub with

Draft Regulator

Summary of Contents for SUPER SJ125

Page 11: ...3 1 2 4 5 6 7 8 9 Furnace Features SJ125 ...

Page 13: ...1 2 3 4 5 6 7 Furnace Features BJ90 13 ...

Page 46: ...SUPER JACK SJ125 Exploded Views Parts Lists 46 ...

Page 48: ...BIG JACK BJ90 Exploded Views Parts Lists 48 ...

Page 53: ...Notes ...

Page 54: ...Notes Notes ...

Page 55: ...Notes ...