LIMITED ONE YEAR WARRANTY

Jackco Transnational Inc. warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material or

workmanship for a period of one (1) year from the original date of purchase. If the defective equipment or tool is determined to be covered under

this warranty, it shall be repaired or replaced at manufacturer's discretion without charge, provided that the equipment or tool must be returned

with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This warranty shall not apply to damage due to accident,

negligent use, and lack of maintenance, abuse or applications other than the specific function the equipment or tool is designed for.

No other warranties, expressed or implied, including those of merchantability or fitness for particular purpose shall be applicable to Jackco

except as specifically stated herein. In no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive

damage of any nature caused by the sale or use of the equipment or tool.

Note: This warranty gives the original purchaser specific legal rights which may very from state to state.

Jackco Transnational Inc. © 201

8

Azusa

, CA

888-452-2526 www.jackco.com

Maintenance

Regularly lubricate all moving parts of the jack. Pay special attention to the lift screw and related

linkages.

• A meidum weight lubricating grease sould be used on all external moving parts, such as bearing

surface, pivot points tilt screws, etc.

• Regularly check the oil level. With the saddle fully lowered, remove the oil filler screw, and check

the oil level. Oil should be at the bottom of the filler screw holes. Fill if nessary.

• Use only hydraulic jack oil. Do not use hydraulic brake fluid.

• If the jack fails to operate, check the oil level and/or bleed until before seeking service.

• Do not use this jack as a wash rack when washing or steam cleaning transmissions.

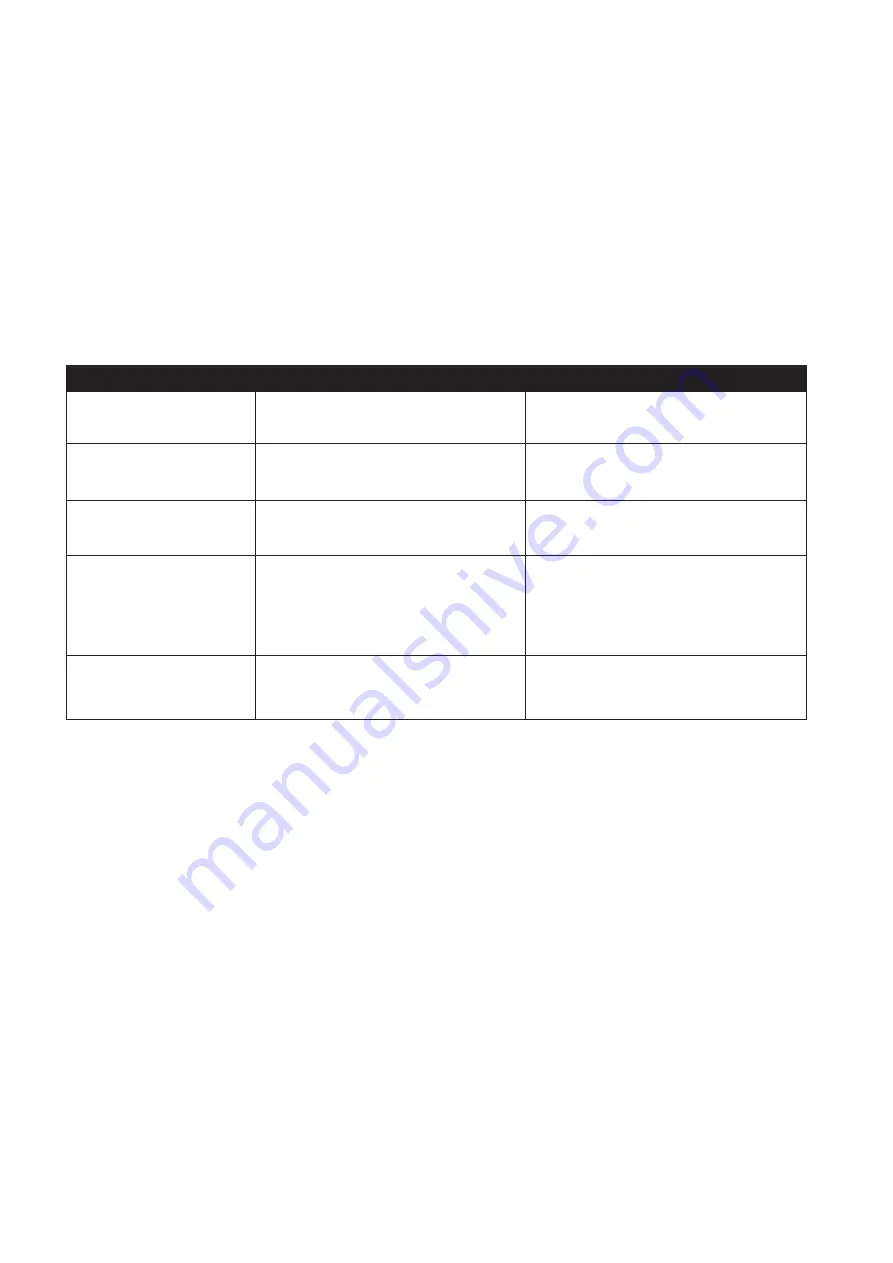

Problem

Cause

Solution

Jack will not lift load

• Overload condition

• Air supply inadequate

• Remedy overload condition

• Ensure adequate air supply

Jack bleeds off after lift Overload condition

Remedy overload condition

Jack will not lower after

unloading

• Resevoir overfilled

• Linkages Dinding

• Drain fluid to proper level

• Clean and lubricate moving parts

Poor lift performance

• Fluid level low

• Air trapped in system

• Ensure proper fluid level

• With ram fully retracted, remove

oil filler screw / vent screw to

let pressurized air escape, then

reinstall oil filler screw/ vent screw

Will not lift to full

extension

Fluid level low

Ensure proper fluid level

Trouble Shooting