Specifications

Lifting Capacity

Lifting Height

Min Height

Max Height

Shipping Weight Working Pressure

20 Ton

12.4 inch 315 mm 8.3 inch 210 mm 20.6 inch 525 mm 112.4 Lbs 51 kg

101-145 psi

Inspection

Prior to each use, visually inspect for leaking hydraulic oil, damaged, loose or missing parts. If jack

is worn or damaged, remove from service and contact your equipment dealer / service center for

repair.

Maintanence

Check oil level. With the jack in an upright position and the ram completely retracted, open the

release valve (turn counter-clockwise) and remove the filler plug. The oil level should be just up to

the hole. Fill if necessary with clean hydraulic jack oil.

Lubricate internal components. With the release valve open, manually pump the handle several

times.

Keep the jack clean. Occasionally lubricate the handle socket pivot point, extension screw, release

screw thread, and air valve to prevent corrosion. Noted: The safety valve is not allowed to be

adjusted.

Operation

1. Tightly close the release valve knob (located on top of the "T" handle) by turning it clockwise.

2. Center the load on the jack saddle. Connect the air supply, and squeeze the air valve lever to

raise the load. Release the air valve lever to stop movement.

3. Transfer the load to support stands.

4. To lower the jack, open the release valve knob by SLOWLY turning it counterclockwise.

NOTE: To adjust the handle, pull up and then release the lever to lock it in one of three positions

Bleeding the Jack

Air bubbles can become trapped inside the hydraulic system, reducing the efficiency of the jack.

Purge air from the system as needed by following steps:

1. With the jack sitting on its base and the ram retracted, bleed air by opening the release valve.

2. Pump for 10 seconds.

Pump Prime Instructions

The air/hydraulic pump may lose its prime during shipment or after long periods without use. To

prime the pump, follow these steps:

1. Remove the upper cover.

2. Loosen the hex socket bolt one-half turn.

(See Figure 1)

3. Close the release valve.

4. Operate the air pump while repeatedly

tightening and loosening the bolt.

5. When the piston begins to rise,

tighten the bolt. Verify that the piston

can rise to the maximum height position.

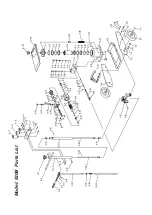

Summary of Contents for 820B

Page 4: ...Model 820B Parts List...