ProTIG 500 AC/DC

Operating Manual

Page 36

26. Maintenance and safety check

This unit should be serviced in regular intervals dependent on Operating times and working place conditions.

Before opening the machine switch off the plug!

- Clean unit inside by vacuum cleaner according to degree of soiling.

Attention:

This Welding unit has to be safety checked every year by JÄCKLE Company or another special qualified

electrician according to the harmonized standard

IEC 60974 – 4

Safety, maintenance and inspection of arc welding equipment in use

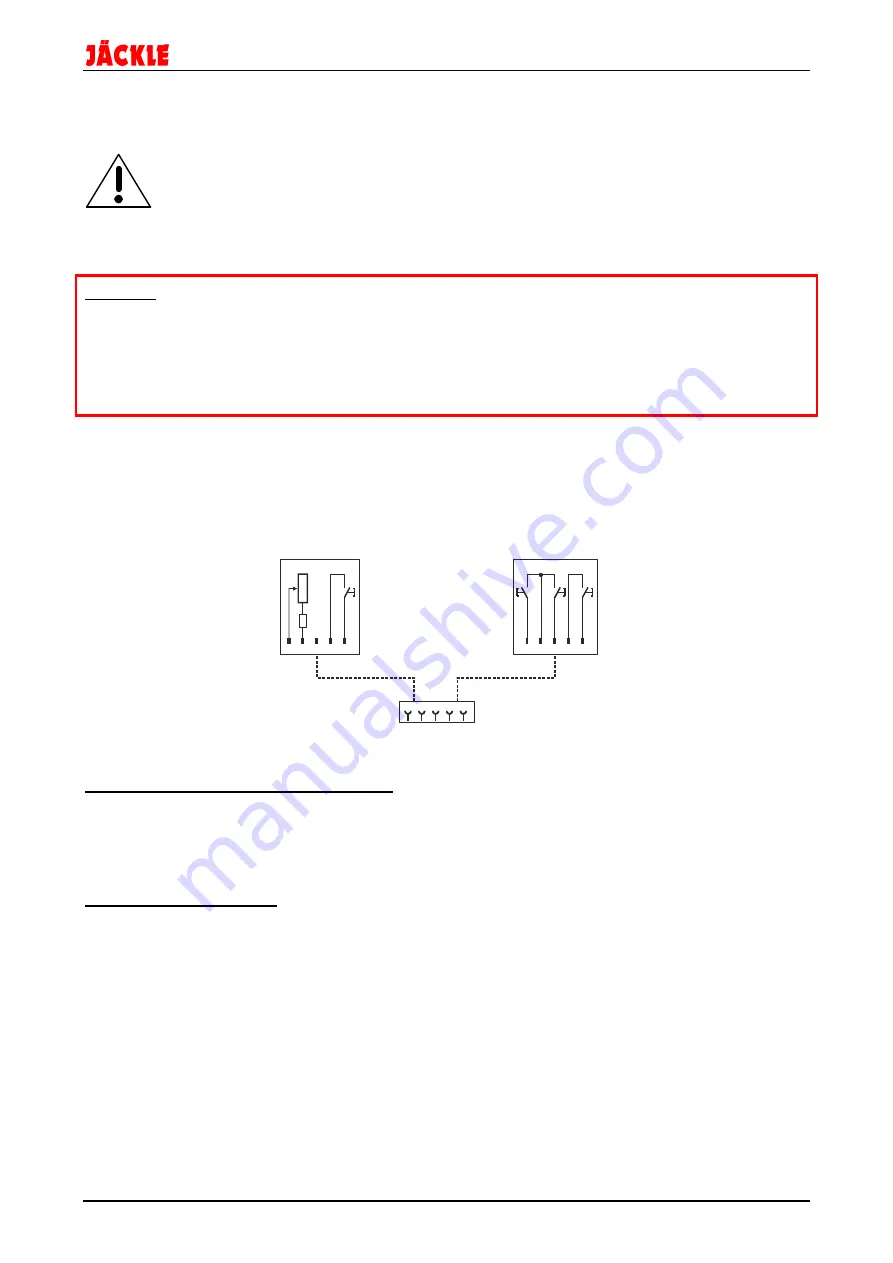

27. Description of the remote control units

The following remote controls are available on the machine:

- TIG welding torch with up / down buttons:

Only a torch with 1 torch trigger and optional up / down buttons can be connected to the machine.

With the torch trigger, the welding process is started and ended.

With the up / down buttons the power of the machine can be adjusted up and down.

NOTE: If the Job menu (Chapter 21) is activated it can be changed with the up / down keys to move between

stored jobs.

- Foot pedal (Display ECF):

With the optional foot pedal, the welding process can be started and stopped. Using the pedal, the welding

power can be changed from minimum to the currently selected maximum power (with the knob).

The maximum power can be adjusted in standby mode with the rotary knob.

NOTE:

The foot pedal works only in 2-cycle mode.

In addition, the slope up and slope-down time should be set to 0.

When connected, the upper display shows ‘ECF’.

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

Fernbedienungsdose 5-polig

Remote control socket 5-pole

DW

UP

BT

BT

Fußpedal

Foot remote

Poti

Up/Down Brenner

Up/Down Torch

10k

5

6

0

R