ProPuls 320C

Operating manual

Page 48

DW. USB:

Error:

Read and save error file

Weld:

Read and save welding data

Jobs:

Read and save jobs

Config.:

Read and save machine settings

All:

Read and save all 4 listed data sets

UP USB:

Jobs:

Save jobs in the machine

Config:

Save machine settings in the machine

All:

Save all data in the machine

UPG. USB:

STW PM:

Update torch PCB

STW FE:

Update wire feed PCB software

STW IR:

Update robot interface software

STW PS:

Update main PCB software

17.11 Error codes

All recognized errors in the display are shown with a duration in 00:00.00 (HRS:min:Sec)

The error codes are listed described in chapter 24.

In order to go back to a menu or leave the entire menu, repeatedly press the key MODE/MATERIAL.

18. Operation / welding

Before welding, please pay attention to the following points:

•

Check the diameter of the contact tips and the wire diameter, both must correspond.

•

Press the button wire feed in until the wire comes out of the torch tip.

•

Connect the gas hose to the gas cylinder and open the cylinder slowly.

•

Set the gas pressure on the pressure regulator to the appropriate value (approx. 1.3-1.7 bar)

•

Press the gas testing button and set the gas flow to a value between 8.5 and 20l/min

tip:

Wire diameter x 10

e.g.: 1.2 mm x 10 = 12 l/min

•

The system is ready to weld.

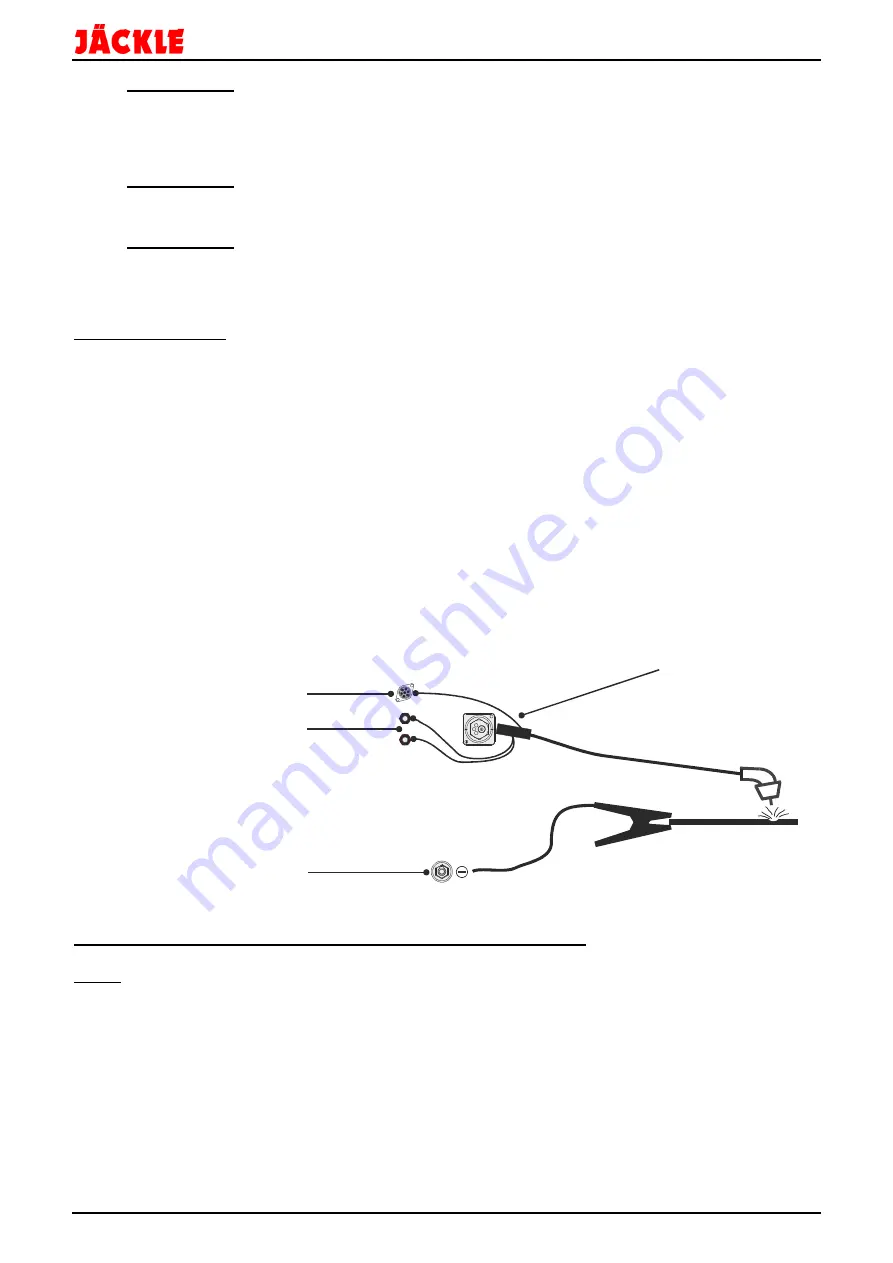

Brenner

Zentralanschluss

Central

torch connection

Massebuchse

Workpiece socket

Anschluss up/down Brenner

Connection up/down torch

Wasservorlauf ‘blau-kalt’ DN 5

water flow ‘blue-cold’ DN 5

Wasserrücklauf ‘rot-heiß’ DN 5

water runback ‘red-hot’ DN 5

18.1 MIG PULSE – MIG Double PULSE - MIG/MAG automatic

NOTE:

All functions and parameters are exactly described under point 16 control elements.

The functional sequence is described.

All these welding processes, are synergic welding programs.

For easy operation, it is only necessary to select the correct welding program and welding power. All other

parameters are regulated by the machine itself.

This allows operating personnel with little experience to achieve good welding results.

A variety of welding programs have already been saved in the machine.

(see program selection panel in the wire feed flap)

Summary of Contents for ProPuls 320 Compact

Page 2: ......

Page 66: ...ProPuls 320C Operating manual Page 62 25 Ersatzteile spare parts Frontansicht front view...

Page 68: ...ProPuls 320C Operating manual Page 64 Seitenansichten side view...

Page 73: ...ProPuls 320C Operating manual Page 69 27 Schwei programme Program table...

Page 74: ...ProPuls 320C Operating manual Page 70...

Page 75: ......