ProPuls 320C

Operating manual

Page 52

The desired welding current can be configured.

Furthermore, the following parameters can be changed individually.

Arc force

The arc-force function prevents the electrode sticking to the workpiece during welding, thus overheating

the electrode and making it unusable.

That means that the power source increases the welding current for a short period of time to prevent

adhesion and ensures a trouble-free welding process, even in the case of electrodes that are difficult to

weld (configure using the Fx button).

HOT start

Is an increase of the welding current during arc ignition. This increase should prevent lack of fusion at

the start of the welding seam and cold tacks.

(configure using Fx button)

Electrode material type

3 different types of electrodes can be welded.

Basic electrodes (basic), rutile electrodes (rutile) and stainless steel electrodes (Cr-Ni)

(configure using the Material button)

VRD display (Voltage Reduction Device)

VRD means voltage reduction at the output. This function applies a maximum level of

voltage of <13V at the terminals. However, this means reduced performance ignition

characteristics of the electrodes.

VRD OFF: Uo= 63V, VRD ON: Uo=13V

This function is deactivated by default.

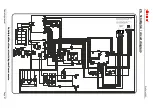

In order to switch on VRD, the front plate has to be unscrewed when the unit is switched off and the

VRD jumper on the PCB just behind it has to be removed as shown in the figure.

Activation takes place by setting the jumper.

Using the following rule of thumb, an average for the level of welding current can be determined:

Welding current = 50 x (electrode diameter- 1 )

Example: 3.2 mm electrode

I = 50 x (3.2 -1 ) = 50 x 2.2 = 110 A

18.5 TIG welding with LIFT-ARC function / pulsed

NOTE:

All functions and parameters are exactly described under point 16 control elements.

The functional sequence is described.

ATTENTION:

In the welding process TIG, the no-load voltage is applied to both output sockets. Careful, risk of

short circuits!

Massebuchse

Workpiece socket

+ Buchse Elektrode / WIG

+ socket MMA / TIG

Vorne / front

Gas

Summary of Contents for ProPuls 320 Compact

Page 2: ......

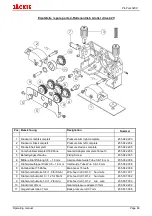

Page 66: ...ProPuls 320C Operating manual Page 62 25 Ersatzteile spare parts Frontansicht front view...

Page 68: ...ProPuls 320C Operating manual Page 64 Seitenansichten side view...

Page 73: ...ProPuls 320C Operating manual Page 69 27 Schwei programme Program table...

Page 74: ...ProPuls 320C Operating manual Page 70...

Page 75: ......