10

BUILT IN PROPANE CYLINDER ENCLOSURES:

1. Built in cylinder enclosures which completely enclose the cylinder must have both of the following:

a. At least one unobstructed ventilation opening on the exposed exterior side of the enclosure located within 5

in (127mm) of the top of the enclosure. The opening must have a total free area of more than 20 square

inches (130 cm square) for a 20lb (9.1kg) cylinder.

b. At least one ventilation opening on the exposed, exterior side of the enclosure located 1 in (25.4mm) or

less from the floor level. The opening must have total free area of more than 10 inches squared (65 cm

squared) for a 20 lb (9.1 kg) cylinder. The upper edge must be no more than 5 inches (127 mm) above the

floor level.

2. Every opening must be large enough to permit the entrance of a 1/8 inch (3.2mm) rod.

3. The cylinder valve must be readily accessible for hand operation. A door on the enclosure to gain access

to the cylinder valve is acceptable, provided it is non-locking and can be opened without the use of tools.

The cylinder valve must be visible.

4. There must be a minimum clearance of 2 inches (51mm) between the floor of the LP-gas cylinder

enclosure and the ground.

5. The enclosure must be designed so that the LP-gas cylinder can be connected, disconnected and the

connections inspected and tested outside the cylinder enclosure. Any connections that can be disturbed

when installing the cylinder in the enclosure must be accessible be for testing inside the enclosure.

6. Maximum Cylinder Size: 20 lbs. (9 Kg)

7. Measurement: (approximately) Diameter: 12

’’(30.5cm) X Height: 18” (45.7cm):

8. USA: All LP cylinders used with this grill must be constructed and marked in accordance with the

Specifications for LP (Propane) Gas Cylinders

of the US Department of Transportation (D.O.T.). Refer to

your propane cylinder collar for markings.

9. CANADA: All propane cylinders used with this grill must be constructed and marked in accordance with the

National Standard of Canada, CAN/CSA-B339;

Cylinders, Spheres and Tubes for the Transportation of

Dangerous Goods and Commission.

Refer to your propane cylinder collar for markings

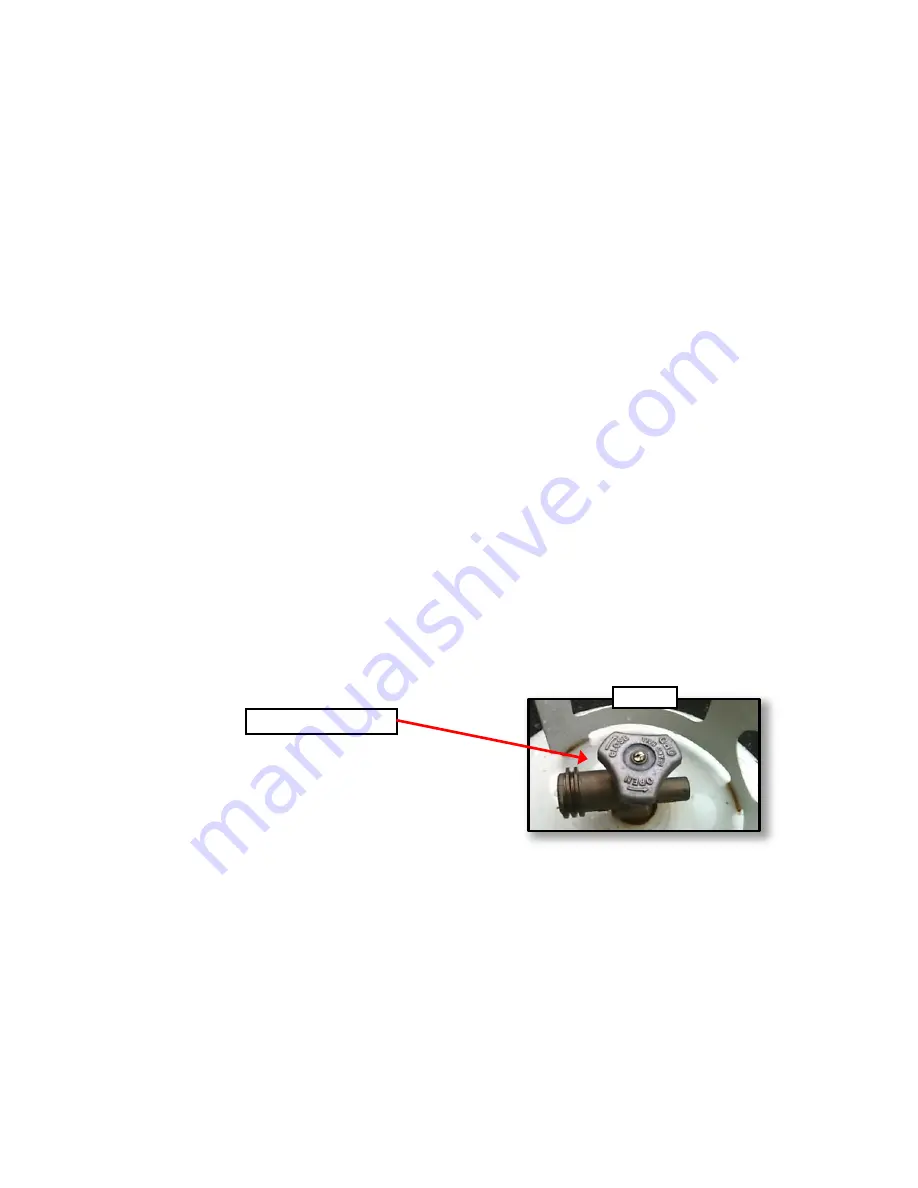

10. Cylinder supply system must be arranged for vapor withdrawal (see figure 8).

11. Cylinder must be equipped with a collar to protect the outlet valve.

12. Cylinders must be rust and dent free: a dented or rusty propane cylinder may be hazardous, and must be

professionally inspected before use.

13. Cylinders must be equipped with QCC Type 1 (Quick Closing Coupling) outlet.

14. Propane Cylinders must be equipped with a safety relief valve.

15. UL listed Overfill Protection Device (OPD); This OPD safety feature is identified by a unique triangular hand

wheel.

Only use cylinders equipped with this type of valve. (Fig. 8)

WHAT TO DO if SAFETY VALVE has tripped:

1. Turn off Propane Cylinder.

2. Disconnect the Propane Hose and Regulator from the Propane Cylinder.

3. Reconnect the Propane Hose and Regulator to the Propane Cylinder.

4.

Turn Gas Valve on slowly.

HANDLING PROPANE CYLINDERS: (NOT Included with Grill)

1. Government regulations prohibit shipping full Propane cylinders. New cylinders (not included) must be

taken to a Propane filling station for filling.

2. A full cylinder is under high pressure; always handle with care, and transport secured and in an upright

position. Protect the valve from accidental damage.

3.

Do not tip the propane cylinder while connecting it to your grill’s regulator

4. If the cylinder is tipped over while connected to your grill, shut it off and disconnect it; then have it checked

Figure 8

Triangular Hand Wheel

Summary of Contents for JLS700BI-NG

Page 22: ...22 Exploded View LUX JLS700Bi ...