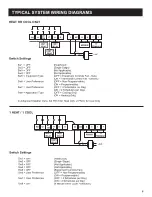

Sw1 - Equipment Type

Sw2 - Equipment Stages

Switch 1 sets the equipment type.

For heat / cool equipment, set the switch to the OFF position

(factory default).

For heat pump equipment, set the switch to the ON position.

Switch 2 sets the equipment stages.

For single stage equipment, set the switch to the OFF position

(factory default). For multi-stage equipment, set the switch to the

ON position.

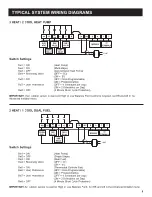

SYSTEM SWITCH FUNCTIONS

Sw3 - Heat Pump Type

Sw4 - Reversing Valve

Sw5 - Fan

Sw6 - Thermostat Mode

Switch 3 is used to select conventional heat pump or dual fuel

operation.

For conventional heat pump, set the switch to the OFF position

(factory default).

For dual fuel operation, set the switch to the ON position.

Switch 4 is used to select the heat pump reversing valve. For ‘O’

reversing valve (energize in cooling), set the switch to the OFF

position (factory default).

For ‘B’ reversing valve (energize in heating), set the switch to the

ON position.

Switch 5 is used to configure the fan operation. For gas systems,

set the switch to OFF (factory default).

For heat pump and electric systems, set the switch to ON position.

Switch 6 is used to set the thermostat mode.

For programmable, set the switch to the ON position.

For non-programmable, set the switch to the OFF position

(factory default).

Sw7 - Schedules

Sw8 - Compressor Delay

OFF = 4 schedules per day (factory default).

ON = 2 schedules per day.

OFF = 4 minute short cycle protection (factory default).

ON = Disabled.

FACTORY DEFAULT SETTINGS

SWITCH

ON/OFF

FUNCTION

1 - Equipment Type

OFF

Heat / Cool

2 - Equipment tages

OFF

Single Stage

3 - Heat Pump Type

OFF

Conventional Heat Pump

4 - Reversing Valve

OFF

‘O’ Reversing Valve

5 - Fan

OFF

Equipment Controls Fan

6 - Thermostat Mode

OFF

Non-programmable

7 - Schedules

OFF

4 Schedules per Day

8 - Compressor Delay

OFF

4 Minute Short Cycle Protection Enabled

5