AJ-64 Conveyor Series Technical Manual 7610-003-30-93

Issued: 05-02-2006 Revised: N/A

SECTION 5: PARTS SECTION

87

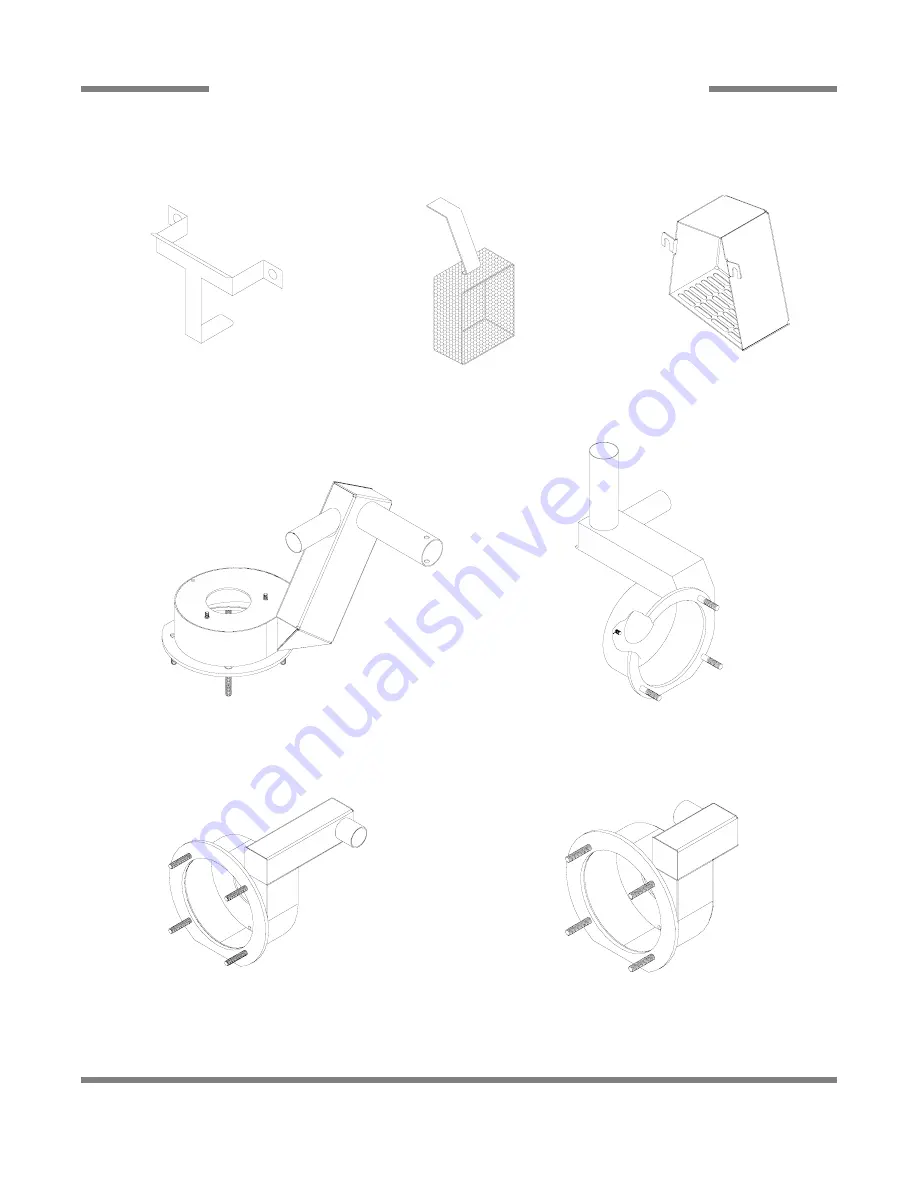

PREWASH & WASH PUMP WELDMENT

The wash pump weldment is a single part. Separate pieces

of the weldment are not available for purchase. The weld-

ment is used for the wash pump in all models covered in this

manual. The weldment may be ordered using part number

05700-041-68-88.

Prewash Intake Strainer Weldment

05700-021-74-96

Prewash Strainer Bracket

05700-021-74-94

The prewash pump weldment is a single part. Separate

pieces of the weldment are not available for purchase.

Prewash Pump Weldment

AJ-86/AJ-100 Left to Right models: 05700-002-10-62

The prewash pump weldment is a single part. Separate

pieces of the weldment are not available for purchase.

Prewash Pump Weldment

AJ-86/AJ-100 Right to Left models: 05700-002-11-96

Intake Suction Scoop Weldment

05700-021-87-60

The power rinse pump weldment is a single part. Separate

pieces of the weldment are not available for purchase.

Power Rinse Pump Weldment (AJ-100’s)

05700-031-81-47

The pump weldment is secured to the pump plate (through the actual tub wall) using the following fasteners:

Nut, Hex, 3/8”-16

05310-276-01-00

Washer, Flat, 3/8”

05311-176-01-00

Lockwasher, Split, 3/8”

05311-276-01-00

Summary of Contents for AJ-100

Page 1: ...53 SECTION 5 PARTS SECTION ...

Page 61: ...113 SECTION 6 ELECTRICAL SCHEMATICS ...

Page 94: ...146 SECTION 7 JACKSON MAINTENANCE REPAIR CENTERS ...

Page 101: ......