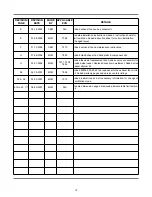

L

e

ft to

R

ig

h

t

Dr

iv

e

Uni

t

Le

ft

S

ide

Dr

iv

e

Un

it

Front V

ie

w

Right

S

ide

3/4"

(19 mm)

Tabl

e Turndow

n

Fl

ange 3/4"

Max

21"

(533 mm)

R

a

c

k

Ra

il H

e

ig

h

t

A

bove D

ishtabl

e

1/4" (6mm) - 5/16" (8mm)

R

a

c

k

Ra

il

Tub

Tabl

e

U

s

e

S

ilic

one S

eal

er

B

e

tw

een Tabl

e and

Li

p of Machi

ne to

P

revent Leakage

Re

c

o

m

m

e

nde

d Ta

bl

e

Fa

br

ic

a

ti

o

n

N

o

te

: T

u

b

W

ill Ac

c

e

p

t

a Tabl

e Fl

ange

U

p

to 24 7/8"

(632 mm)

1

2

[15mm]

84 [2134mm]

75

1

2

[1919mm]

62

1

2

[1590mm]

34 [864mm]

29 [737mm]

6 [152mm]

8

1

2

[218mm]

21 [533mm]

25 [635mm]

12 [307mm]

25 [635mm]

10 [254mm]

7 [178mm]

D

E

A

C

B

18

1

2

[467mm]

4 [102mm]

Tabl

e to Tabl

e

Overal

l

W

ith D

oors Open

R

ear of

M

a

chi

n

e

D

ish C

learance

14 [356mm]

Mi

ni

mum

10

" H

ig

h

Table

B

a

cksplash

Sc

ra

p

Tr

ough

7

1

2

[190mm]

C

B

Legend

A

- Machi

ne w

a

ter i

n

le

t 3/4"

N

P

T 180°F

H

i-temp,140°F Low

-temp mi

ni

mum

B

- E

lectri

c

al

connecti

on

C

- D

rai

n connecti

on 1-1/2"

N

P

T

D

- V

ent col

la

r - Opti

onal

E

- V

ent cow

l standard

F - 3/4"

N

P

T S

team connecti

on

G - 3/4"

N

P

T C

ondensate return

H

- S

team el

ectri

c

al

connecti

on

J - 1"

N

P

T S

team connecti

on

K

- 3/4"

C

ondensate connecti

on

L - 3/4"

N

P

T Incomi

ng 110°F w

a

ter

connecti

on

M - 3/4"

N

P

T 180°F w

a

ter to di

shmachi

ne.

N

o

te: A

ll verti

c

al

di

mensi

ons are +

/- 1/2"

from fl

oor due to adj

ustabl

e bul

le

t feet.

60

1

4

[1530mm]

8 [204mm]

7 [178mm]

10 [254mm]

12

1

2

[316mm]

G

F

17

1

2

[445mm]

4"

(102 mm) w

ide x 16"

(406 mm)

l

ong cutout i

n

V

ent C

o

w

l/

S

p

la

sh

S

h

ie

ld

. S

h

ipped w

ith C

o

ver P

late.

Fl

oor S

ink Or D

rai

n

W

ith 3"

(76 mm)

Mi

ni

mum D

rai

n Li

ne

25 [637mm]

4 1/2 [114mm]

44 [1118mm]

52 [1321mm]

60 [1524mm]

8 [204mm]

14 [355mm]

Sc

ra

p

Trough

Mi

ni

mum

21 [535mm]

B

1 [25mm]

66

5

8

[1692mm]

65

1

2

[1665mm]

13

5

8

[346mm]

A

6

3

8

[162mm]

11

5

8

[295mm]

15

3

4

[400mm]

16

3

8

[417mm]

43 [1092mm]

11

1

4

[285mm]

13

5

8

[345mm]

23

3

4

[604mm]

38 [966mm]

6

1

4

[159mm]

5

7

8

[148mm]

4

3

8

[110mm]

8

5

8

[218mm]

H

J

L

M

K

L

H

J

M

F

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: 09-29-2007

SECTION 1: SPECIFICATION INFORMATION

AJ-44 STEAM - LEFT TO RIGHT

9