16

07610-001-76-22-N

On 3-Phase machines only, correct pump motor rotation must be verified before

the machine is operated. Failure to do so can result in damage to the machine and

components.

1. Follow the Power Up section.

2. Locate the wash pump motor and identify the arrow decal which shows the correct

motor rotation (if no decal is present, correct rotation is toward front of machine).

3. Flip AUTOMATIC/DELIME button to DELIME.

4. Flip ON/OFF button to ON.

5.

Observe rotation of motor fan and quickly flip ON/OFF button to OFF.

6. If rotation is incorrect, disconnect electrical power and reverse the L1 and L2

connections at terminal block shown in the previous section.

The machine should be located with an adequate exhaust hood or ventilation system with

provisions for venting. This is essential to permit efficient removal of the condensation ex

-

haust. Ensure the exhaust system is acceptable in accordance with applicable codes and

standards.

Any damage caused by steam and/or moisture due to improper ventilation

is NOT covered under the warranty.

Machine ventilation requirements:

• Load End: 200 CFM

• Unload End: 400 CFM

The exhaust system must be sized to handle this volume for the machine to operate

properly.

The thermostats on this machine have been set at the factory and should only be adjusted

by an authorized service agent.

There are two Table Limit Switch options available. Click on the instruction icons below for

install guides.

Striker

Switch

Whisker

Switch

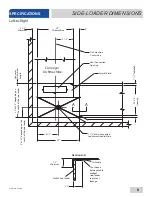

INSTALLATION

INSTRUCTIONS

THERMOSTATS

VENTILATION

NOTICE

TABLE LIMIT

SWITCH OPTION

MOTOR

ROTATION

i

CAUTION!

On

3-Phase machines

only, correct pump

motor rotation

must be verified

before operation!

!

CAUTION

RO

TA

TIO

N

Motor Fan

Summary of Contents for AJ-44

Page 72: ...64 07610 001 76 22 N PARTS AJ 66 RACK RAILS Left to Right Right to Left 1 4 2 3 4 5 6 7 1 ...

Page 84: ...76 07610 001 76 22 N SCHEMATICS AJ 44CGP 208 230 V 60 HZ 1 PHASE AJ 44CGP SCHEMATIC ...

Page 85: ...07610 001 76 22 N 77 SCHEMATICS AJ 44CGP 208 230 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Page 86: ...78 07610 001 76 22 N SCHEMATICS AJ 44CGP 460 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Page 87: ...07610 001 76 22 N 79 SCHEMATICS AJ 66CGP 208 230 V 60 HZ 1 PHASE AJ 66CGP SCHEMATIC ...

Page 88: ...80 07610 001 76 22 N SCHEMATICS AJ 66CGP 208 230 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...

Page 89: ...07610 001 76 22 N 81 SCHEMATICS AJ 66CGP 380 460 600 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...