AJX-44 & AJX-54 Series Technical Manual 7610-003-60-98

Issued: 01-19-2009 Revised: 01-30-2009

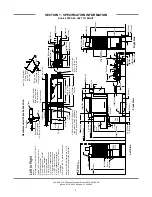

SECTION 1: SPECIFICATION INFORMATION

OPERATING CHARACTERISTICS

2

RACKS PER HOUR:

AJX-44, 66, 80, 54, 76, 90 (High Temp)

225

AJX-44, 66, 80, 54, 76, 90 (Low Temp)

209

DISHES OR GLASSES PER HOUR:

AJX-44, 66, 80, 54, 76, 90 (High Temp)

5625

AJX-44, 66, 80, 54, 76, 90 (Low Temp)

5225

PREWASH TANK CAPACITY (GALLONS):

AJX-66, 76

17.25

AJX-80, 90

17.25

WASH TANK CAPACITY (GALLONS):

AJX-44, 66, 80, 54, 76, 90

20.4

PREWASH PUMP CAPACITY (GPM):

AJX-66, 76

120

AJX-80, 90

270

WASH PUMP CAPACITY

GALLONS PER MINUTE (ALL MODELS):

270

VENTING REQUIREMENTS (CFM)(100% CAP.):

INPUT END

200

OUTPUT END

400

TOTAL

600

CONVEYOR SPEED (FPM):

AJX-44, 66, 80, 54, 76, 90 (High Temp)

6.2

AJX-44, 66, 80, 54, 76, 90 (Low Temp)

5.75

GALLONS PER RACK:

AJX-44, 66, 80, 54, 76, 90 (High Temp)

.69

AJX-44, 66, 80, 54, 76, 90 (Low Temp)

.79

WATER TEMPERATURES:

AJX-44, 66, 80, 54, 76, 90 MODELS:

PREWASH (RECOMMENDED)(AJX-66,76,80,90) 110-140

F

WASH (MINIMUM)

160

F

RINSE (MINIMUM)

180

F

FLOW PRESSURE (PSI)

15

FLOWRATE (GPM):

AJX-44, 66, 80, 54, 76, 90 (High Temp)

2.57

AJX-44, 66, 80, 54, 76, 90 (Low Temp)

2.74

STEAM COIL TANK HEAT (TS MODELS ONLY):

STEAM INLET PRESSURE (PSIG)

10-20

STEAM CONNECTION NPT

3/4”

CONSUMPTION @ 15 PSIG (lbs/hr):

60

MOTOR ELECTRICAL CHARACTERISTICS:

DRIVE MOTOR HP

1/4

WASH MOTOR HP

2

PREWASH MOTOR HP:

AJX-66CE/CS & AJX-76CE/CS MODELS

1

AJX-80CE/CS & AJX-90CE/CS MODELS

2

NOTE: Always refer to the machine data plate for specific

electrical and water requirements. The material provided

on this page is for reference only and may be subject to

change without notice.

Summary of Contents for AJX-44 Series

Page 8: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 27: ...20 SECTION 2 INSTALLATION OPERATION INSTRUCTIONS ...

Page 38: ...31 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 42: ...35 SECTION 4 TROUBLESHOOTING SECTION ...

Page 45: ...38 SECTION 5 PARTS SECTION ...

Page 92: ...85 SECTION 6 ELECTRICAL SCHEMATICS ...

Page 103: ...96 SECTION 7 JACKSON MAINTENANCE REPAIR CENTERS ...

Page 110: ...AJ 44T Series Technical Manual 7610 003 07 21 Issued 03 21 2006 Revised N A ...