07610-003-92-84-T

10

Electrical and grounding conductors must comply with the applicable portions of the

National Electric Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Refer to the machine data plate for machine operating requirements, machine voltage,

total amperage, and serial number.

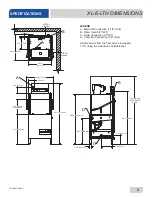

1. Remove control box top.

2. Install conduit into pre-punched holes in back of control box.

3.

Route power wires and connect to terminal block and grounding lug.

4. Install service wires (L3 for 3-Phase, LTH only) to the appropriate terminals as

they are marked on terminal block.

5. Install grounding wire into lug provided.

6. Apply anti-oxidation product to—and tighten—all power connections.

On LTH 3-Phase machines only, correct pump motor rotation must be verified before

the machine is operated. Failure to do so can result in damage to the machine and

components.

1. Follow Filling the Wash Tub section.

2. Locate wash pump motor and identify arrow decal which shows correct motor

rotation (if no decal is present, correct rotation is away from the pump volute).

3. Flip NORMAL/DELIME switch on back of control box to DELIME

and start the

machine.

4.

Observe rotation of motor fan and quickly stop the machine.

5. If rotation is incorrect, disconnect electrical power and reverse the L1 and L2

connections at terminal block.

This machine may be operated with or without an exhaust hood depending on local

or state codes.

The thermostats on these machines have been set at the factory. They should only be

adjusted by authorized service personnel.

ELECTRICAL POWER

CONNECTIONS

Disconnect electrical

power at the breaker

or disconnect switch

and lockout /tagout

in accordance with

procedures and codes.

VENTILATION

INSTRUCTIONS

INSTALLATION

THERMOSTATS

MOTOR ROTATION

(LTH 3-PHASE ONLY)

i

CAUTION!

On LTH 3-Phase

machines only, correct

pump motor rotation

must be verified

before operation!

!

CAUTION

Pump Volute

Motor Fan

Summary of Contents for CONSERVER XL HH

Page 61: ...07610 003 92 84 T 53 XL E LTH BOOSTER TANK PARTS 16 ...

Page 65: ...07610 003 92 84 T 57 SCHEMATICS XL E XL HH 115 V 60 HZ 1 PHASE ...

Page 66: ...07610 003 92 84 T 58 SCHEMATICS XL E XL HH 208 V 60 HZ 1 PHASE ...

Page 67: ...07610 003 92 84 T 59 SCHEMATICS XL E LTH 208 230 V 60 HZ 1 3 PHASE ...

Page 68: ...07610 003 92 84 T 60 SCHEMATICS XL E FL 115 V 60 HZ 1 PHASE ...

Page 69: ......