TROUBLESHOOTING SECTION

10

WARNING:

Inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain

procedures in this section require electrical tests or measurements while power is applied to the machine.

Exercise

extreme caution at all times.

If test points are not easily accessible, disconnect power, attach test equipment and reap

ply power to test. When replacing electrical parts, disconnect power at source circuit breaker.

Possible Cause

Action

Obstruction in pump housing or wash

manifold.

Disassemble and clear.

Pump impeller worn or broken.

Replace the pump impeller.

Power supply shorted to ground.

Check for loose wires or burned

connections.

Faulty door switch or detergent safety

switch.

Check for loose or wet connections at

switch and at wire connectors. Bypass

switch to verify that switch is problem;

replace if required.

Pump impeller jammed.

Clear impeller.

Wash pump motor faulty.

Check motor voltage and amp load. If amp

load is over 12 amps, replace the motor.

Circuit breaker is too small.

Replace with properly sized breaker. Refer

to the data plate.

Loose wire connection.

Tighten wires to timer drain microswitch.

Drain hole/strainer obstructed.

Clear obstructions.

Not enough time to drain.

Adjust fill cam on timer and/or the drain

cam.

Drain linkage binding.

Repair drain parts.

Faulty drain microswitch on timer.

With power off and the drain cam on the

timer in the home position, remove the

WHITE/YELLOW wire from the microswitch.

Faulty drain microswitch on timer.

Measure the continuity between the

ORANGE wire on the microswitch and the

tab that the WHITE/ YELLOW wire is

attached onto. If there is no continuity,

replace the microswitch.

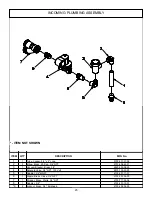

Drain solenoid defective.

Check for voltage at solenoid valve during

the drain cycle. Replace if voltage is

present.

Faulty drain ball.

Replace drain ball.

Obstructed drain hole.

Clear obstruction.

Drain linkage is binding.

Repair drain mechanism parts.

Shorted sanitizer microswitch on cam timer. If there is not 120V between the ORANGE

and GREY wires on the sanitization pump

motor microswitch when switch is out of the

home position, replace the switch.

Shorted prime switch.

If there is not 120 volts between GREY and

WHITE/RED wires to prime switch, replace

the switch.

Loose or broken wire.

Tighten connections to microswitch.

Faulty sanitizer microswitch on cam timer.

When sanitizer cam is in home position,

measure voltage between ORANGE and

GREY wires on the microswitch. If 120V,

replace switch.

Sanitizer pump does not run during the

cycle, but runs when primed.

Sanitizer pump runs continuously.

Machine will not hold water.

Symptom

Machine keeps tripping the service breaker.

Low pumped water pressure.

Machine will not drain.