13

07610-004-43-79-Q

Proper ware preparation helps ensure good results and fewer re-washes. If not done

properly, ware might not come out clean and efficiency of the dishmachine will be

reduced. Scraps should always be removed from ware before being loaded into

a rack. Pre-rinsing and pre-soaking are good ideas, especially for silverware and

casserole dishes.

Place cups and glasses upside-down in racks so they don't hold water during the

cycle. This machine sanitizes as well as cleans. To do this, ware must be properly

prepared before being placed in machine.

1. Follow the Filling the Wash Tub section, ensuring temperature is at least 155 °F

and status displays "READY."

2. Open door completely.

3.

Slide rack into machine.

4.

Close door.

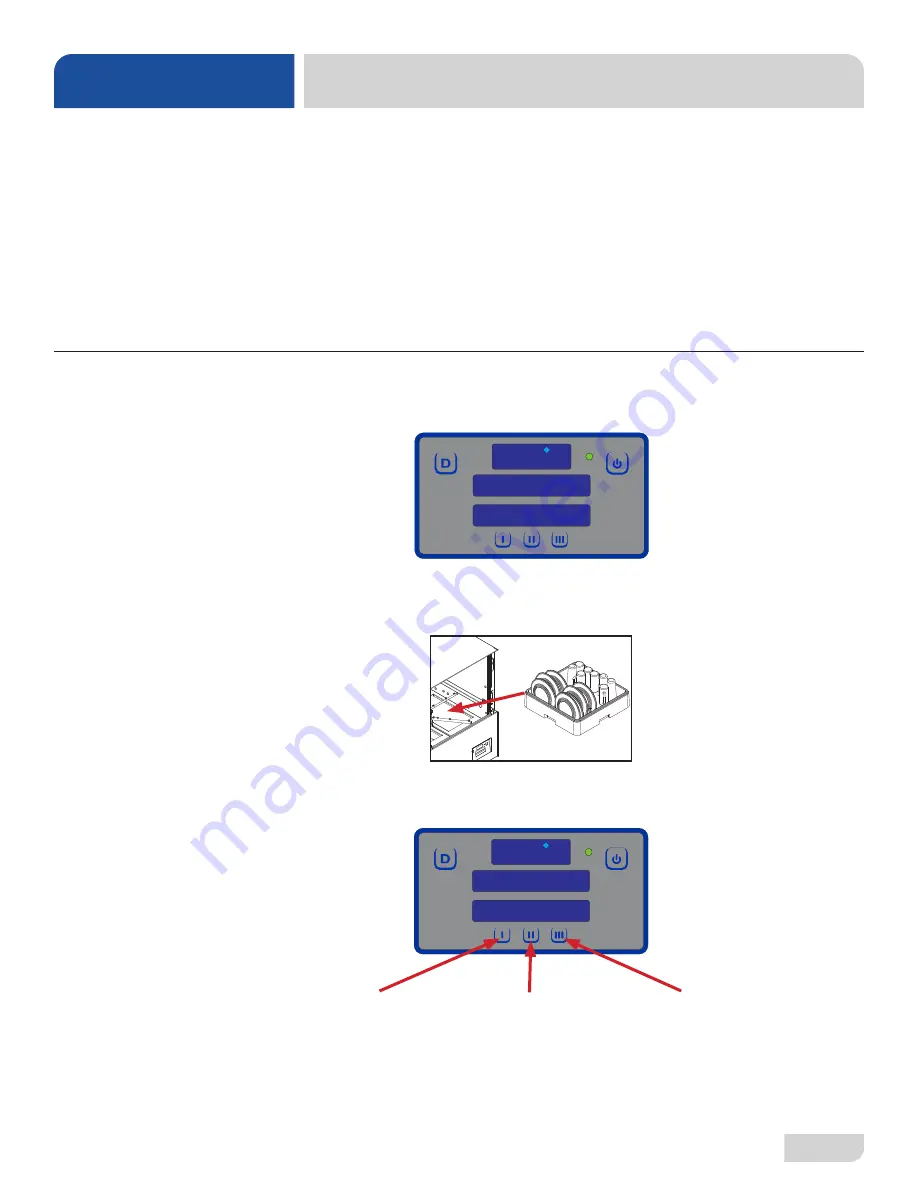

5. Choose cycle.

WASHING A RACK

OF WARE

WARE

PREPARATION

OPERATING INSTRUCTIONS

OPERATION

1 5 5

F

R E A D Y

C Y C L E 1

1 5 5

F

R E A D Y

C Y C L E 1

Cycle I

100 Seconds

Normally-soiled Ware

Cycle II

168 Seconds

Heavily-soiled Ware

Cycle III

268 Seconds

Extremely-soiled Ware

If Cycle II or Cycle III is chosen, machine will stay in that cycle until another is chosen.