07610-004-99-71-B

26

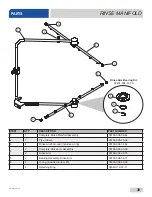

ITEM

QTY

DESCRIPTION

PART NUMBER

1

1

Power Connection Decal

09905-011-47-35

2

1

Terminal Block Box

05700-004-36-47

1

Terminal Box Cover (not shown)

05700-003-27-70

3

1

Strain Relief

05975-003-37-56

4

1

Terminal Block Track

05700-000-43-60

5

2

Terminal Block

05940-500-02-19

6

2

Locknut, 10-24 Hex with Nylon Insert

05310-373-01-00

7

1

Decal, L1, N

09905-011-62-72

8

1

Ground Lug

05940-200-76-00

6

7

5

4

8

1

3

2

TERMINAL BLOCK BOX

PARTS