07610-004-29-29-D

8

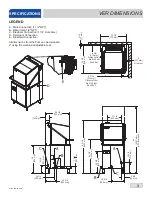

INSTRUCTIONS

INSTALLATION

Take care not to confuse

static pressure with

flow pressure!

PLUMBING

CHECK

Read the Plumbing section on the previous page before proceeding

Install the water supply line to the machine using copper pipe. A water shut-off valve

should be installed in the water line between the main supply and the machine to

allow access for service.

If water hardness tests at greater than 3 GPG, install the Scaltrol Water Treatment

system (see the Plumbing Options page) into the water line before the machine’s

incoming water connection point. If water hardness tests at 3 GPG or less, install the

water supply line directly to the machine’s incoming water connection point.

The water supply line must be capable of 10 ± 2

PSI “flow” pressure at the recommended

temperature indicated on the data plate.

Do not confuse static pressure with flow pressure. Static pressure is the line pressure

in a “no flow” condition (all valves and services are closed). Flow pressure is the

pressure in the fill line when the fill valve is opened during the cycle.

The manufacturer recommends the installation of a pressure regulating valve (PRV)

in the incoming water line to ensure proper flowrate at all times and offers these

devices as options. See the Plumbing Options page. The PRV comes standard on

the DynaTemp VER but ships inside the machine. Click

here

for install instructions.

The manufacturer also recommends the installation of a water hammer arrestor in the

incoming water line and offers these devices as options. See the Plumbing Options

page. This prevents line hammer/hydraulic shock—induced by the solenoid valve as

it operates—from causing damage to the equipment.

DynaTemp S comes with lines to connect the source steam. Connect steam lines to

the machine according to all applicable codes. See machine data plate for information

concerning steam flow pressure.

Click

here

for the Steam Booster manual.

1.

Slowly turn on the water supply to the machine after the incoming fill line and drain

line have been installed.

2. Check for any leaks and repair as required.

CAUTION!

All leaks must be repaired before placing the machine in operation

WATER SUPPLY

CONNECTION

!

CAUTION

NOTICE

STEAM LINE

CONNECTION

i

i

A water hardness test

MUST be performed.

Summary of Contents for Dynatemp Series

Page 2: ......

Page 39: ...07610 004 29 29 D 32 11 10 9 12 13 19 20 4 18 17 16 14 15 1 2 3 5 6 7 8 21 TUB PARTS ...

Page 41: ...07610 004 29 29 D 34 11 10 13 18 19 4 17 16 15 1 2 3 5 7 8 6 12 14 9 STEAM TUB PARTS ...

Page 45: ...07610 004 29 29 D 38 PARTS WASH RINSE ARMS 1 2 3 4 5 6 7 8 9 10 11 ...

Page 67: ......