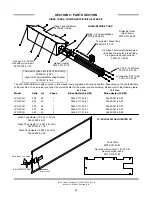

ITEM

QTY

DESCRIPTION

Mfg. No.

1

1

Electrical Control Panel Weldment

05700-011-41-79

2

1

Bushing, Snap

05975-210-03-00

3

1

Contactor, Motor

05945-002-74-20

4

8

Screw, 10-32 x 3/8” Phillips Truss Round Head

05305-173-12-00

5

1

Locknut, 10-24 S/S Hex with Nylon Insert

05310-373-01-00

6

1

Wire Lug

05940-200-76-00

7

1

Grommet, 1 1/8" Heyco

05975-210-08-00

8

1

Decal, Copper Conductors

09905-011-47-35

9

1

Decal, Ground, L1, L2

09905-101-40-82

10

1

Bracket, Relay Mounting

05700-002-37-85

11

1

Relay, 220-240 Volt

05945-111-89-75

12

4

Screw, 6-32 x 3/8” Sems with External Tooth Lockwasher

05305-002-25-91

13

1

Decal, Timer

09905-011-40-70

14

1

Timer, 60 HZ

05945-121-41-60

14

1

Timer, 50 HZ

05945-002-13-34

14

1

Timer, 5 Minute

05945-121-44-89

15

1

Track, Terminal 3 5/16"

05700-000-43-60

16

2

Block, Snap-in Terminal

05940-500-02-19

17

4

Locknut, 1/4”-20 S/S Hex with Nylon Insert (not shown)

05310-374-01-00

JP-24 Technical Manual 7610-002-49-79 Rev. D

Issued: 03-06-2006 Revised: N/A

SECTION 6: PARTS SECTION

ELECTRICAL PANEL ASSEMBLY (JP-24/F 208-240 VOLT)

31

1

6

7

13, 14, 12

12

4

15

9

10

11

16

2

3

4

4

8

5

Summary of Contents for Hot Water Sanitizing Undercounter Dishmachines JP-24

Page 2: ......

Page 6: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 10: ...SECTION 2 INSTALLATION OPERATION INSTRUCTIONS 5 ...

Page 16: ...SECTION 3 PREVENTATIVE MAINTENANCE 11 ...

Page 18: ...SECTION 4 TROUBLESHOOTING 13 ...

Page 21: ...16 SECTION 5 SERVICE PROCEDURES ...

Page 34: ...SECTION 6 PARTS SECTION 29 ...