41

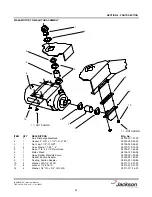

SECTION 6: PARTS SECTION

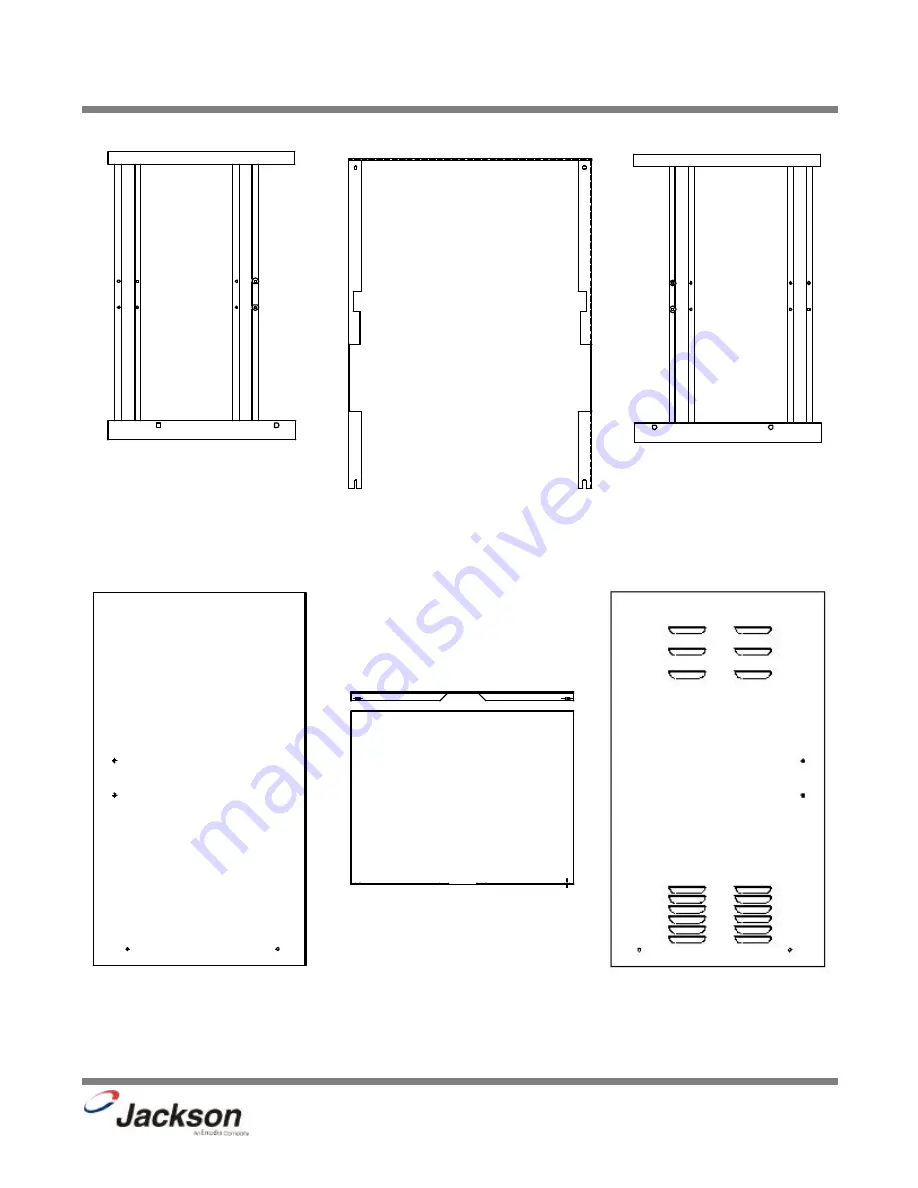

FRAME, SHROUD, & PANEL COMPONENTS

JP-24BPNSU Technical Manual

7610-002-38-50 Rev. D (11/11/2005)

Left Frame Weldment

05700-011-73-85

Right Frame Weldment

05700-011-73-86

The swivel feet used on the unit may be ordered using 05340-108-02-00

Shroud Weldment

05700-031-38-15

Secured with 10-32 x 1/2” Long Screws

05305-173-04-00

Right Dress Panel

05700-041-38-08

Left Dress Panel

05700-041-38-37

Top Panel

05700-041-38-38

The Panels are secured with 10-32 x 1/2” Truss Head Screws, 05305-011-39-36

Summary of Contents for JP-24BPNSU

Page 9: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 12: ...4 SECTION 2 INSTALLATION OPERATION INSTRUCTIONS ...

Page 18: ...10 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 20: ...12 SECTION 4 TROUBLESHOOTING ...

Page 23: ...15 SECTION 5 SERVICE PROCEDURES ...

Page 32: ...24 SECTION 6 PARTS SECTION ...

Page 50: ...SECTION 7 ELECTRICAL DIAGRAMS 42 ...

Page 56: ...SECTION 8 JACKSON MAINTENANCE REPAIR CENTERS 48 ...

Page 63: ......