Summary of Contents for Puritan PA-1

Page 2: ......

Page 7: ...1 SECTION 1 SPECIFICATION INFORMATION ...

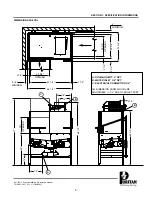

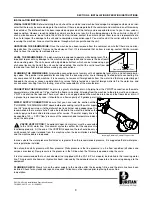

Page 14: ...SECTION 2 INSTALLATION OPERATION INSTRUCTIONS 8 ...

Page 24: ...18 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 26: ...20 SECTION 4 TROUBLESHOOTING ...

Page 31: ...25 SECTION 5 SERVICE PROCEDURES ...

Page 38: ...THIS PAGE IS INTENTIONALLY LEFT BLANK 32 ...

Page 39: ...33 SECTION 5 PARTS SECTION ...

Page 70: ...SECTION 6 ELECTRICAL SCHEMATICS 64 ...

Page 75: ......