31

6. Your repair kit comes with a new plunger. Examine the old

one and ensure that the mating surface is not damaged or cut.

Also inspect the rubber seal on the top of the plunger to

ensure it is in good condition and not torn.

7. If any of these conditions are present, replace the old

plunger with the new one from your kit. Verify that the new

plunger is also free from defects. If it is not, contact your

Puritan representative immediately.

8. The plunger should drop into the vacuum breaker and seat.

Ensure it is not flipped upside down (the orange seal ring

should be up towards the top of the vacuum breaker).

9. Pick up the cap and examine it. With a soft towel, remove

any grit, grime or debris that may have gotten caught in the

threads of both the cap retainer or the vacuum breaker body.

There is an O-ring that should be present on the cap retainer

as well. Regardless of the condition of the plunger, this O-ring

should be replaced once the cap is removed. Using a small

flathead screwdriver, remove the old O-ring.

10. With the new O-ring in place, screw the cap back on the

vacuum breaker body. The cap needs to only be hand tight

(snug).

AFTER MAINTENANCE ACTIONS

1. Reconnect the incoming water (if disconnected)

and turn on. Then restore power to the unit. Run the unit for

at least 10 minutes to ensure there are no leaks. If any prob-

lems arise please contact your Puritan representative.

SPECIAL PARTS

To order the kit with components and instructions:

Components of 1/2” Repair Kit

Part No.: 85284156

Mfg. No.: 06401-003-06-23

Components of 3/4” Repair Kit

Part No.: 85284164

Mfg. No.: 06401-003-06-24

PA-1/PA-2 Series Installation & Operation Manual

7610-002-24-11 Rev. J (11/02/2005)

SECTION 5: SERVICE PROCEDURES

VACUUM BREAKER REPAIR PARTS KIT (CONTINUED)

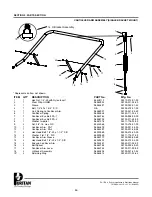

Removing the plunger

Examining the seal ring on the plunger

Examining the plunger seating surface

Replacing the O-ring

Summary of Contents for Puritan PA-1

Page 2: ......

Page 7: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 14: ...SECTION 2 INSTALLATION OPERATION INSTRUCTIONS 8 ...

Page 24: ...18 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 26: ...20 SECTION 4 TROUBLESHOOTING ...

Page 31: ...25 SECTION 5 SERVICE PROCEDURES ...

Page 38: ...THIS PAGE IS INTENTIONALLY LEFT BLANK 32 ...

Page 39: ...33 SECTION 5 PARTS SECTION ...

Page 70: ...SECTION 6 ELECTRICAL SCHEMATICS 64 ...

Page 75: ......