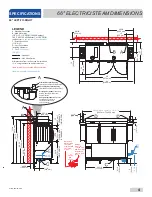

07610-004-33-05-E

3

4 MIN

[102 m

m

]

12

[305 mm]

22 1/2

[572 mm]

16

[4

06

m

m

]

20

[5

08

m

m

]

15

[3

81

m

m

]

30

[762 m

m

]

44

[1118 mm]

64

[1626 mm]

Machine

Drain Line

1 1/2 [38 mm]

MIN, Must NOT

Be Reduced.

Pitch 1/4

[6 mm] per ft.

Must Install

Machine Drain

Line above

3 [76 mm] MIN

Floor Drain

or Sink

1 1/2

[38 mm]

MIN

Air-gap

4

[102 mm]

5

[1

27

mm

]

15

1/

8

[38

4 m

m

]

8

[2

02

m

m

]

6 7/8

[2

10

m

m

]

21

[533 mm]

ADJUSTABLE FROM 51 1/2 TO 54

[1308 mm TO 1372 mm]

Primary Electrical Opening

(Provided on both ends of machine.)

Secondary Electrical Opening

(Provided on both ends of machine.)

Single-point (Option):

uses only

primary opening to power the

entire machine.

Dual-point (Standard):

also uses

secondary opening for a

separate connection to

only the booster.

LEGEND

A - Electrical Connection

B - Main Water Inlet

(1/2" NPT, 110 °F MIN (18 kW Booster),

140 °F MIN (12 kW Booster), or 180 °F MIN

(No Booster

or Supplied from Steam Booster)

)

C - Drain Connection

(1 1/2" NPT)

D - Vent Connections

(Including Dampers)

E - Steam Connection

(3/4" NPT)

- Open Door

- High Hood Option

All dimensions from the floor can be increased

1 3/4” using the machine’s adjustable feet.

Items in red are not supplied with the machine.

Items in blue are for the Steam option.

A

25 1/4

[642 mm]

25

[6

35

mm

]

CLEARANCE (HIGH HOOD)

34

1

/4

[8

70

m

m

]

TABLE HEIGHT

8

[202 mm]

73

3/4

[1

873 m

m

]

11 3/4

[297 mm]

4 MIN

[102 mm]

19 3/4

[502

mm

]

CLEARANCE (STANDARD)

62 1/4

[1581

m

m

]

68 1/2

[1740

m

m

]

68 1/8

[1730

m

m

]

A

B

SPECIFICATIONS

44" ELECTRIC/STEAM DIMENSIONS

44" RIGHT-TO-LEFT