37

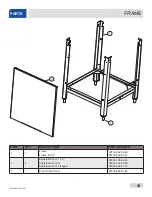

07610-002-23-32-AD

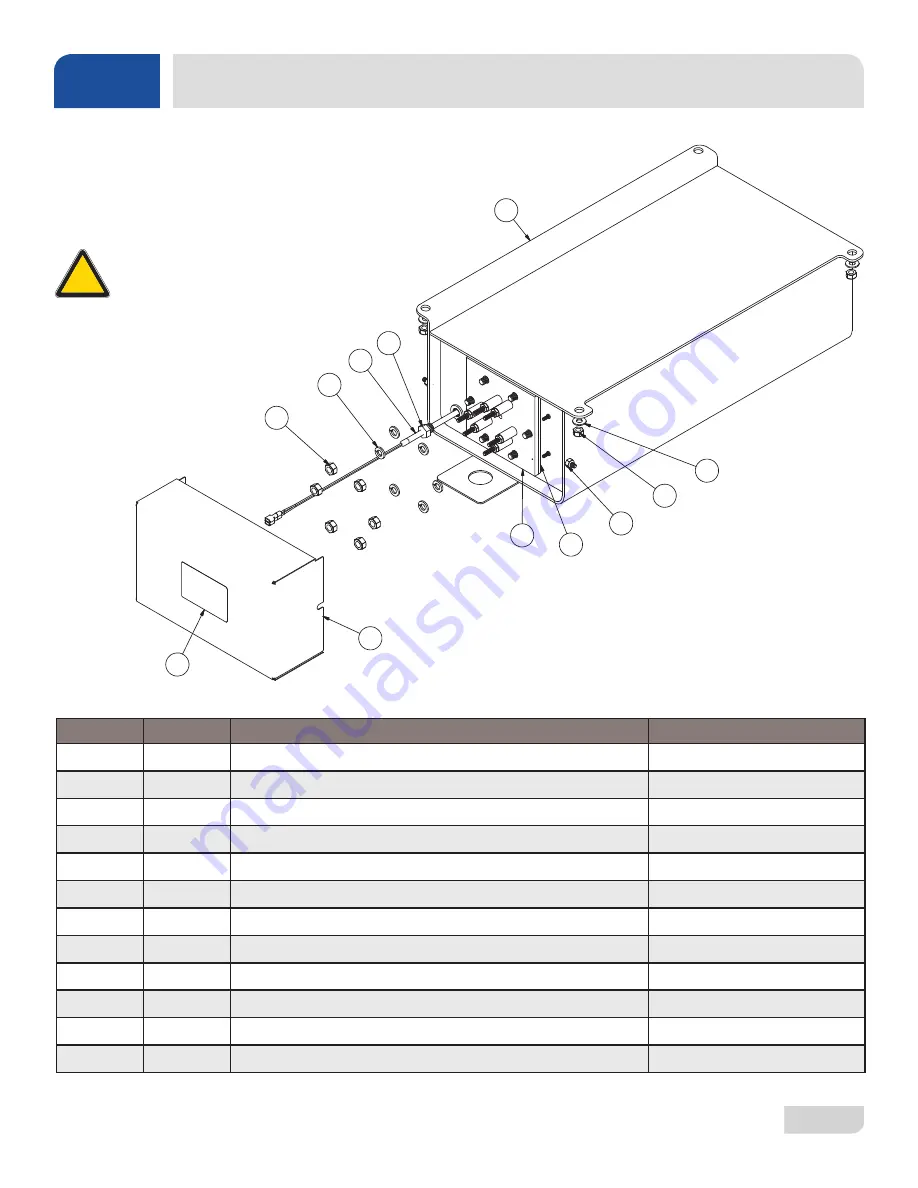

ITEM

QTY

DESCRIPTION

PART NUMBER

1

1

Tank, Rinse

05700-002-10-19

2

1

Gasket, Rinse Heater

05330-200-02-70

3

1

Heater, Rinse

See "Heaters" page.

4

1

Probe, Thermistor 4"

06685-004-17-26

5

1

Fitting, Thermostat Brass

05700-011-73-73

6

6

Nut, Hex, 5/16-18

05310-275-01-00

7

6

Lockwasher, 5/16", Split

05311-275-01-00

8

2

Locknut, 10-24 with Nylon Insert

05310-373-01-00

9

4

Locknut, 1/4-20 with Nylon Insert

05310-374-01-00

10

4

Washer, 1/4", Flat

05311-174-01-00

11

1

Cover, Rinse Tank

05700-002-16-51

12

1

Decal, Warning-Disconnect Power

09905-004-08-16

Complete Assemblies

208-230 V, 14 kW 70◦

Rise - 06401-004-55-19

208-230 V, 12 kW 40◦ Rise - 06401-004-55-20

460 V, 14 kW 70◦

Rise

- 06401-004-55-21

460 V, 12 kW 40◦ Rise - 06401-004-55-22

RINSE TANK

PARTS

CAUTION!

HH-E & HH-E-VER

machines with serial numbers after

18C355287 have the rinse tank on

the previous page.

!

CAUTION

Summary of Contents for TEMPSTAR HH-E

Page 35: ...07610 002 23 32 AD 26 1 5 4 2 3 6 7 10 8 9 HOOD PARTS...

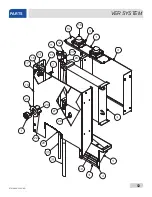

Page 61: ...07610 002 23 32 AD 52 VER SYSTEM PARTS 18 24 23 12 11 16 17 14 21 22 20 19 27 28 29...

Page 67: ...07610 002 23 32 AD 58 SCHEMATICS HH E VER 208 230 V NEW RINSE TANK...

Page 68: ...59 07610 002 23 32 AD SCHEMATICS HH E VER 460 V NEW RINSE TANK...

Page 69: ...07610 002 23 32 AD 60 SCHEMATICS HH E VER 208 230 V OLD RINSE TANK...

Page 70: ...61 07610 002 23 32 AD SCHEMATICS HH E VER 460 V OLD RINSE TANK...

Page 71: ...07610 002 23 32 AD 62 SCHEMATICS NB 208 230 V...

Page 72: ...63 07610 002 23 32 AD SCHEMATICS NB 460 V...

Page 73: ...07610 002 23 32 AD 64 SCHEMATICS HH S 208 230 V...

Page 74: ...65 07610 002 23 32 AD SCHEMATICS SDI OPTIONS...

Page 75: ......