13

07610-003-61-42-U

PROGRAMMING EXHAUST FAN TIMER

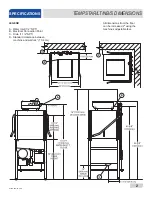

INSTALLATION

1.

Apply power (120, 208, or 240 VAC) to the A1 & A2 terminals.

Timer Wiring with Correct Wire Colors

2. Hold down the SET and ADJ buttons for at least 3 seconds.

3. Repeatedly press the ADJ button until the letter E appears on the left-hand side.

4.

Press the SET button.

5.

Press the ADJ button until the letters M S appear.

6.

Press the SET button.

7.

Press the ADJ button to adjust the first digit to 2.

8.

Press the SET button.

9.

Press the ADJ button to adjust the second digit to 3.

10.

Press the SET button.

11.

Press the ADJ button to adjust the third digit to 0.

12.

Press the SET button.

13.

Press the ADJ button so there is an arrow facing downward.

14.

Press the SET button.

Light Gray

Dark Gray

Yellow

Red

Red/Yellow

Yellow/Black

Summary of Contents for TEMPSTAR LT

Page 35: ...07610 003 61 42 U 28 26 1 29 28 30 33 34 36 CONTROL BOX ASSEMBLY PARTS ...

Page 67: ...07610 003 61 42 U 60 PARTS VENTLESS SYSTEM ASSEMBLY ...

Page 75: ...07610 003 61 42 U 68 SCHEMATICS 208 230 V 50 60 HZ 1 PHASE ...

Page 76: ...69 07610 003 61 42 U SCHEMATICS 460 V 50 60 HZ 3 PHASE ...

Page 77: ...07610 003 61 42 U 70 SCHEMATICS LT NB 208 230 V 50 60 HZ 1 PHASE ...

Page 78: ...71 07610 003 61 42 U SCHEMATICS LT NB 460 V 50 60 HZ 3 PHASE ...

Page 79: ...07610 003 61 42 U 72 SCHEMATICS STEAM 208 230 V 50 60 HZ 1 3 PHASE ...

Page 80: ...73 07610 003 61 42 U SCHEMATICS SDI OPTIONS ...

Page 81: ...07610 003 61 42 U 74 SCHEMATICS DRAIN QUENCH OPTION ...