Tempstar LT/NB/S/SDS Technical Manual 7610-011-86-35

Issued: 12-07-2007 Revised: N/A

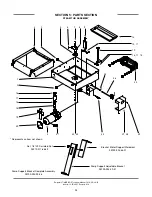

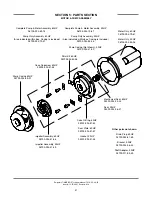

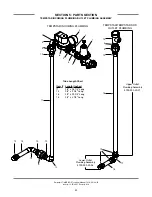

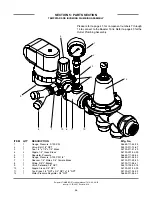

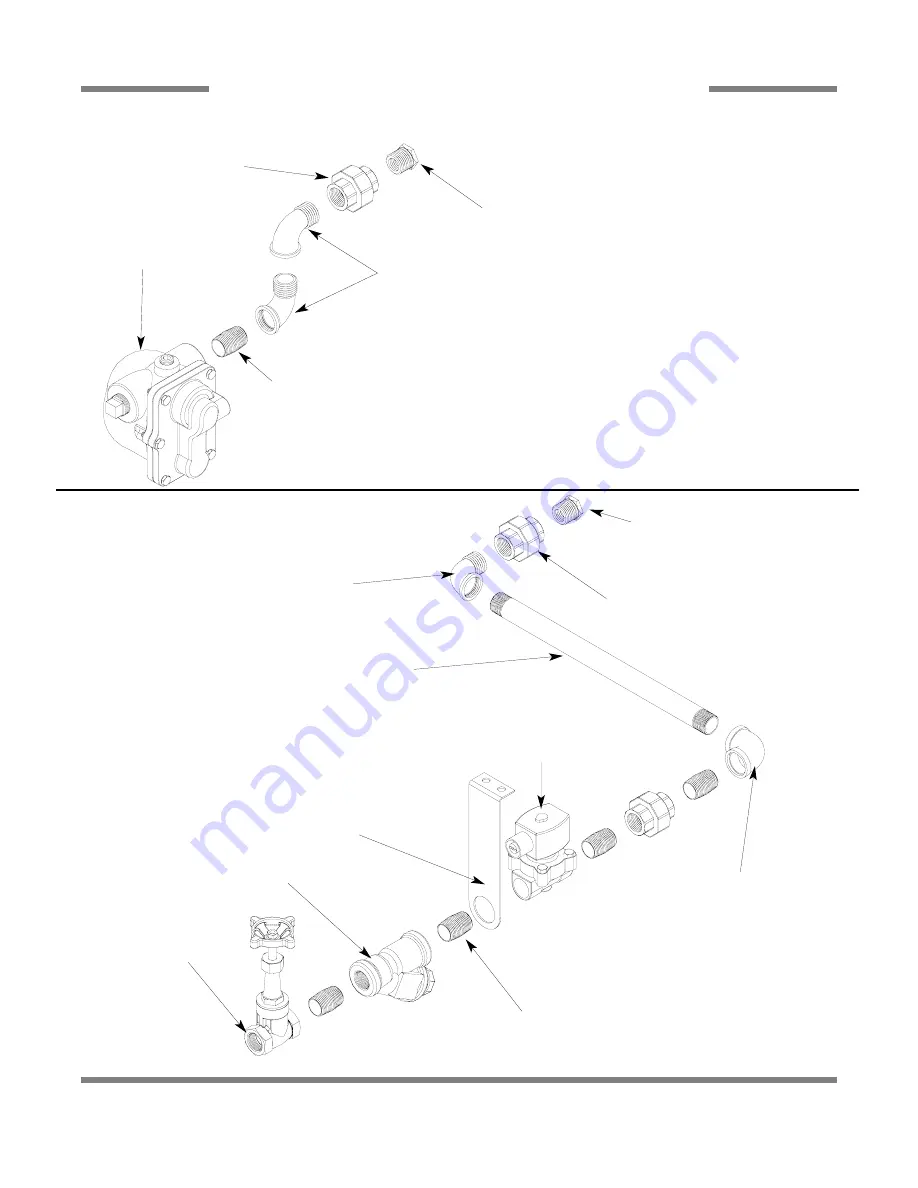

SECTION 5: PARTS SECTION

INCOMING STEAM PLUMBING ASSEMBLIES

39

Union, 3/4’’ NPT, Black Iron

04730-912-01-01

Elbow, 3/4” 90° Street

04730-011-87-37

Elbow, 3/4” 90° Street

04730-011-87-37

Steam Trap, 3/4” NPT F&T

06680-500-02-77

Nipple, Close, 3/4’’ NPT, Black Iron

04730-907-01-00

Bushing, Reducing, 3/4’’ to 1/2’’

04730-911-02-34

Bushing, Reducing, 3/4’’ to 1/2’’

04730-911-02-34

Elbow, 90

°

3/4” NPT Black Iron

04730-011-87-37

Union, 3/4’’ NPT, Black Iron

2 per assembly

04730-912-01-01

3/4” NPT Black Iron Pipe

05700-002-20-83

Gate Valve, 3/4” NPT

04820-100-19-00

Bracket, Steam Plumbing Support

05700-002-20-83

Y-Strainer, 3/4” NPT Black Iron

04730-217-01-32

Solenoid Valve, Steam Plumbing, 220V

04820-002-01-32

Nipple, Close, 3/4’’ NPT, Black Iron

4 per Assembly

04730-907-01-00

To order this complete assembly, use part number:

05700-002-01-55

To order this complete assembly, use part number:

05700-002-01-60

Summary of Contents for TEMPSTAR

Page 2: ......

Page 9: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 16: ...8 SECTION 2 INSTALLATION OPERATION INSTRUCTIONS ...

Page 22: ...14 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 24: ...16 SECTION 4 TROUBLESHOOTING SECTION ...

Page 27: ...19 SECTION 5 PARTS SECTION ...

Page 67: ...59 SECTION 6A ELECTRICAL SCHEMATICS FOR TOP MOUNT UNITS ...

Page 83: ...75 SECTION 6B ELECTRICAL SCHEMATICS FOR SIDE MOUNT UNITS ...

Page 93: ...85 SECTION 6C ELECTRICAL SCHEMATICS FOR OPTIONS ...

Page 96: ...88 SECTION 7 JACKSON MAINTENANCE REPAIR CENTERS ...

Page 103: ......