15

07610-003-61-42-T

DETERGENT CONTROL

Detergent usage and water hardness are two factors that contribute greatly to how

effi ciently your dishmachine will operate. Using detergent in the proper amount can

become, in time, a source of substantial savings. A qualifi ed water treatment specialist

can tell you what is needed for maximum effi ciency from your detergent, but you should

still know some basics so you’ll understand what they are talking about.

First, you must understand that hard water greatly effects the performance of the

dishmachine. Water hardness is the amount of dissolved calcium and magnesium in the

water supply. The more dissolved solids in the water, the greater the water hardness.

Hard water works against detergent, thereby causing the amount of detergent required for

washing to increase. As you use more detergent, your costs for operating the dishmachine

will increase and the results will decrease. The solids in hard water also may build-up as a

scale on wash and rinse heaters, decreasing their ability to heat water. Water temperature

is important in removing soil and sanitizing dishes. If the water cannot get hot enough,

your results may not be satisfactory. This is why Jackson recommends that if you have

installed the machine in an area with hard water, that you also install some type of water

treatment equipment to help remove the dissolved solids from the water before it gets to

the dishmachine.

Second, hard water may have you adding drying agents to your operating cycle to prevent

spotting, when the real problem is deposited solids on your ware. As the water evaporates

off of the ware, the solids will be left behind to form the spotting and no amount of drying

agent will prevent this. Again, using treated water will undoubtedly reduce the occurrences

of this problem.

Third, treated water may not be suitable for use in other areas of your operation. For

instance, coffee made with soft water may have an acid or bitter fl avor. It may only be

feasible to install a small treatment unit for the water going into the dishmachine itself.

Discuss this option with your qualifi ed water treatment specialist.

Even after the water hardness problems have been solved, there still must be proper

training of dishmachine operators in how much detergent is to be used per cycle. Talk

with your water treatment specialist and detergent vendor and come up with a complete

training program for operators. Using too much detergent has as detrimental effects

as using too little. The proper amount of detergent must be used for job. It is important

to remember that certain menu items may require extra detergent by their nature and

personnel need to be made aware of this. Experience in using the dishmachine under a

variety of conditions, along with good training in the operation of the machine, can go a

long way in ensuring your dishmachine operates as effi ciently as possible.

DETERGENT

CONTROL

OPERATION

Summary of Contents for TEMPSTAR

Page 2: ......

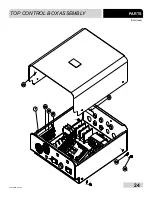

Page 31: ...24 07610 003 61 42 T TOP CONTROL BOX ASSEMBLY PARTS Continued 26 1 29 28 30 33 34 36 ...

Page 66: ...59 07610 003 61 42 T PARTS TEMPSTAR VENTLESS SYSTEM ASSEMBLY ...

Page 77: ...70 TEMPSTAR 460 V 60 HZ 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 79: ...72 TEMPSTAR LT NB 208 230V 50 60HZ 1 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 82: ...75 07610 003 61 42 T SCHEMATICS SDI OPTIONS ...

Page 83: ...76 07610 003 61 42 T DRAIN QUENCH OPTIONS SCHEMATICS ...

Page 85: ......