16

07610-003-61-42-T

DETERGENT CONTROL

Certain dishmachine models require that chemicals be provided for proper operation

and sanitization. Some models even require the installation of third-party chemical

feeders to introduce those chemicals to the machine. Jackson does not recommend or

endorse any brand name of chemicals or chemical dispensing equipment. Contact your

local chemical distributor for questions concerning these subjects.

Some dishmachines come equipped with integral solid detergent dispensers. These

dispensers are designed to accommodate detergents in a certain sized container. If

you have such a unit, remember to explain this to your chemical distributor upon fi rst

contacting them.

As explained before, water temperature is an important factor in ensuring that your

dishmachine functions properly. The data plate located on each unit details what the

minimum temperatures must be for either the incoming water supply, the wash tank

and the rinse tank, depending on what model of dishmachine you have installed.

These temperatures may also be followed by temperatures that Jackson recommends

to ensure the highest performance from you dishmachine. However, if the minimum

requirements are not met, the chances are your dishes will not be clean or sanitized.

Remember, a dish can look clean, but it may not be sanitized. Instruct your dishmachine

operators to observe the required temperatures and to report when they fall below the

minimum allowed. A loss of temperature can indicate a much larger problem such as a

failed heater or it could also indicate that the hot water heater for your operation is not

up to capacity and a larger one may need to be installed.

There are several factors to consider when installing your dishmachine to ensure that

you get the best possible results from it and that it operates at peak effi ciency for many

years. Discuss your concerns with your local chemical distributor and water treatment

specialist before there is a problem.

OPERATION

DETERGENT

CONTROL

(CONTINUED)

Summary of Contents for TEMPSTAR

Page 2: ......

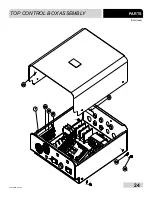

Page 31: ...24 07610 003 61 42 T TOP CONTROL BOX ASSEMBLY PARTS Continued 26 1 29 28 30 33 34 36 ...

Page 66: ...59 07610 003 61 42 T PARTS TEMPSTAR VENTLESS SYSTEM ASSEMBLY ...

Page 77: ...70 TEMPSTAR 460 V 60 HZ 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 79: ...72 TEMPSTAR LT NB 208 230V 50 60HZ 1 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 82: ...75 07610 003 61 42 T SCHEMATICS SDI OPTIONS ...

Page 83: ...76 07610 003 61 42 T DRAIN QUENCH OPTIONS SCHEMATICS ...

Page 85: ......