MAINTENANCE 7

39

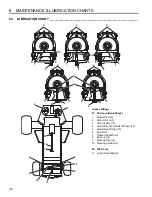

7.18 WHEEL MOUNTING PROCEDURE ____________________________________________

1.

Remove dirt, grease and oil from stud thread. Do not

lubricate threads.

2.

Position wheel on hub and inspect to insure full

contact between mounting surface of wheel and hub

or brake drum.

3.

Finger tighten all hardware, then torque hardware in

criss-cross order; always tighten nuts in the top

position.

4.

Check and re-torque daily until torque is maintained

at 85-95 ft.lbs. (115-128 Nm).

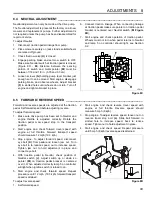

7.19 INSPECTING BLADES ______________________________________________________

1.

Every 50 hours of operation or whenever mower is

removed from mower, carefully examine the blades

to make sure they are in good operating condition.

Blades showing any bends

(G)

, grooves

(H)

or

cracks (

J)

must be replaced.

2.

Any of the above conditions can cause a piece of

the blade to break away and be hurled from the

mower, causing very serious injury to bystanders or

property damage.

3.

A bent blade could have a microscopic crack (G)

that can grow and allow a piece of the blade to

break. Bent blades will also create vibration and

other stress on the machinery.

4.

Dust or sand particles can wear a dangerous groove

in the blade (H) between the air vanes and the flat

portion of the blade that will rapidly grow and

produce a crack (J), permitting a piece of the vane

to break off.

Figure 7C

WARNING

Make sure the mower is parked on a solid and level

surface. Never work on a mower that is supported

only by the jack. Always use jack stands.

If only the front or rear of the mower is raised, place

chocks in front of and behind the wheels that are not

raised.

!

CAUTION

Use care when checking blades to avoid pinching

hands and fingers between blade ends.

WARNING

Never attempt to straighten, weld, or repair a

damaged blade. Always replace a damaged blade.

!

!

G

H

J

HR025