ADJUSTMENTS 4

GB-13

4.4 BRAKES _________________________________________________________________

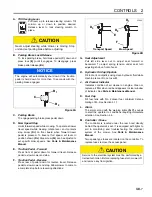

Adjust brakes after replacing or servicing brake assembly,

or if pedal travel becomes excessive.

1. When installing new brake pads, burnish pads by

driving mower at mowing speed while applying a slight

pressure on brake pedal for about 5 seconds. Release

and repeat five times before making the final

adjustment.

2. Fully loosen adjusting nut

(E)

.

3. Disconnect brake return spring

(See Item 14,

Illustration 8.1)

at caliper.

4. By hand, pull cable behind adjusting nut

(C)

away from

pedal until brake pads just contact brake disk. Thread

adjusting nut

(C)

up until it contacts the mounting plate.

Tighten nut

(E)

to lock adjustment in place. Torque nut

(E)

to 20 ft. lb. (27 Nm). Do not over torque or turn

cable.

5. Connect brake return spring. Repeat for second cable.

6. If brakes wear beyond point where they can be

adjusted by the cable, move brake bracket into second

set of holes provided

(D)

and complete adjustment

procedure.

7. Start mower and check operation of brakes. Park

mower on an incline (approx. 16.7° slope) and engage

parking brake. Brake must prevent mower from rolling.

Adjust nut

(C)

as required.

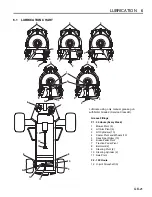

Figure 4C

4.5

NEUTRAL ADJUSTMENT ___________________________________________________

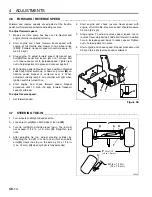

Neutral adjustment can only be made at the drive pump.

The Neutral adjustment is preset at the factory on all new

mowers and replacement pumps. Further adjustment is not

required unless the pump has been disassembled for repair

or service.

To adjust Neutral:

1. Disconnect traction pedal linkage from pump.

2. Place mower securely on jack stands so

All

wheels

are raised off ground.

3. Check that tow valve

(H)

is closed

4. Engage parking brake and set mow switch to Neutral.

Make sure Neutral switch at traction pedal is closed.

(Figure 4E -

M

). Distance between the sensing portion

of switch and metal pointer

(M)

must be between 1/16

and 1/8 in. (1.5 and 3 mm).

5. Loosen screws

(G)

holding pump lever bracket just

enough so it can be moved. Start engine, disengage

parking brake, and observe wheels. Adjust bracket

(F)

in slotted holes until wheels do not turn. Turn off

engine and tighten bracket in place.

6. Connect traction linkage. When connecting linkage at

traction pedal make sure pointer on traction pedal

bracket is centered over Neutral switch (

M

-

Figure

4E

).

7. Start engine and check operation of traction pedal.

Wheels must not turn when pedal returns to Neutral

and lamp 5 on controller should light, see Section 5.

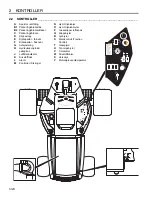

Figure 4D

C

E

D

D

F

H

G

LF014