7 BATTERIES

22

7.5

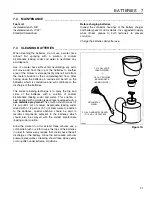

BATTERY CHARGER ______________________________________________________

The battery charger is designed to fully charge the

battery pack. Read the instruction manual included with

the charger for proper operating procedure.

Before charging, the following should be observed:

The charging must take place in an area that is well

ventilated and capable of removing the hydrogen gas

that is generated by the charging process. A

minimum

of

five air exchanges per hour is recommended.

The charging connector components are in good

condition and free from dirt or debris. It is suggested to

apply white lithium grease to both terminals to prevent

corrosion.

The charger connector is fully inserted into the battery

pack receptacle.

The charger connector/cord set is protected from

damage and is located in an area to prevent injury that

may result from personnel running over or tripping over

the cord set.

Install all chargers in accordance with the manufacturers

instructions.

If the charger is operated in an outdoor location, rain

and sun protection must be provided.

Remove AC power cord from outlet before connecting or

disconnecting battery charger to battery pack.

The charging (DC) cord is equipped with a polarized

connector which fits into a matching receptacle on the

battery pack.

If the charger is not operating correctly, unplug charger

from both the AC outlet and the battery pack and check

the fuse.

AC Voltage

The charger is equipped with an input voltage selector

switch located on the rear of the charger. Determine what

input voltage is used in your area and set switch

accordingly before connecting AC power cord. This

charger can be used with the following AC input voltages:

100 - 130 V (Set voltage selector to 115 V (Position 1))

200 - 240 V (Set voltage selector to 230 V (Position 2))

NOTE:

Charger will operate with either a 50 or 60 Hz

input voltage.

Make certain the AC power cord is equipped with an

appropriate plug for the area you live in. The charger is

equipped with a grounding plug, do not attempt to

defeat its functionality.

Note:

The AC power cord included with the battery

charger is used with 115 V - 60 Hz (North America) input

voltage only. If you live in an area where 115 V - 60 Hz

input voltage is not used, a new AC power cord must be

purchased locally.

The battery charger should fully charge the battery pack

in approximately 7 hours with 115V AC input voltage.

Battery charging times may exceed 8 hours in areas

where 100V AC input voltage is used.

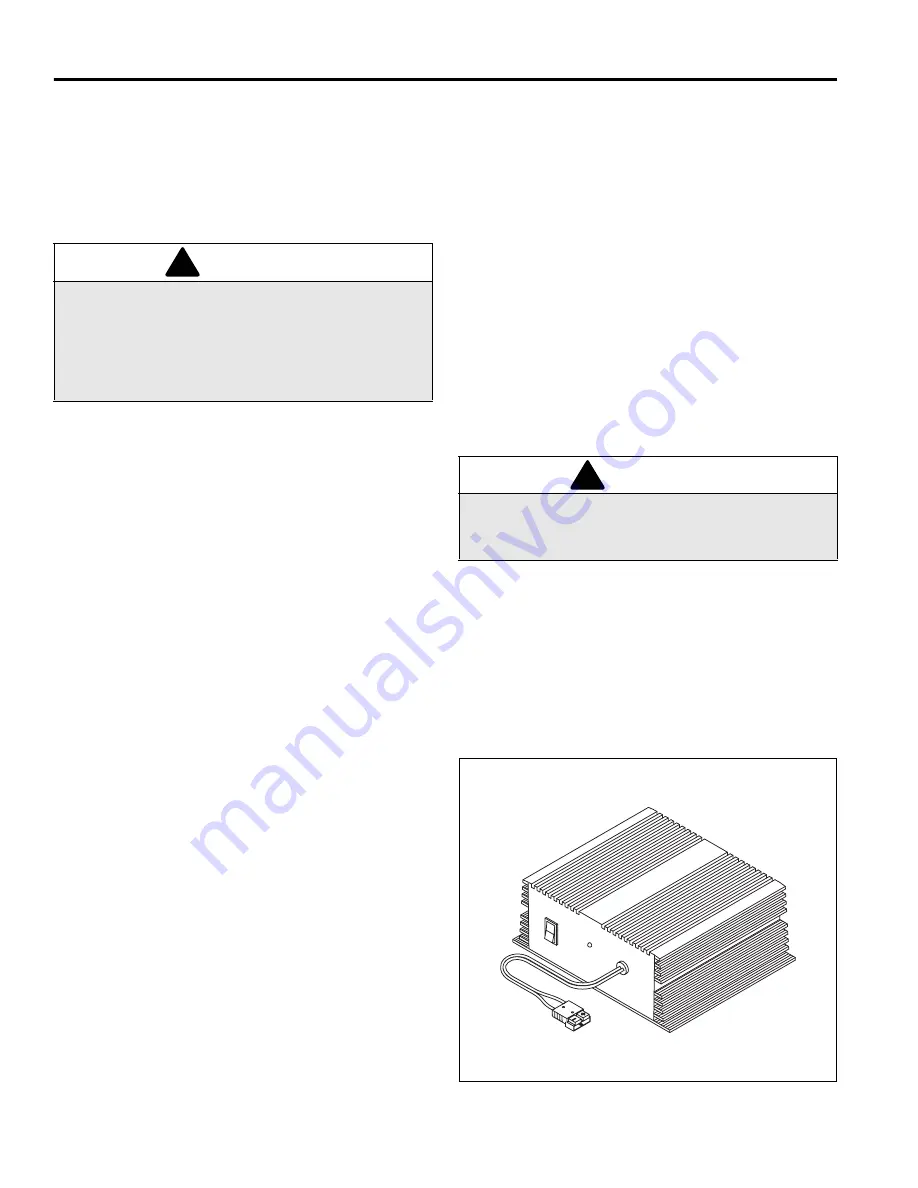

Figure 7B

WARNING

Portable chargers should be mounted on a platform

above the ground, or in such a manner as to permit

the maximum air flow underneath and around the

charger. Serious damage to the charger, overheating

and potential for fire may result if the charger does not

have sufficient air flow.

!

WARNING

An ungrounded electrical device may become a

physical hazard that could result in an electrical shock

or electrocution

!

Po

wer

OFF

Charging Indicator

48

V-Lead Acid Batter

y

Au

tomatic Switch-Mode Charger

GHC4802

ON

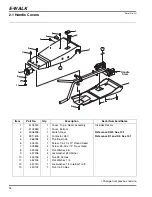

Summary of Contents for E-Walk 62290

Page 1: ...Technical Manual GB E Walk 62290 22 11 Blade Reel 4105380 Rev A...

Page 30: ...11 NOTES 30 11 NOTES...

Page 61: ...61 INDEX...