6 ADJUSTMENTS (ALL UNITS)

30

6

ADJUSTMENTS (ALL UNITS)

6.1 GENERAL ________________________________________________________________

1.

Adjustments and maintenance should always be

performed by a qualified technician. If proper

adjustment cannot be made, contact an authorized

Jacobsen Dealer.

2.

Replace, do not adjust, worn or damaged

components.

3.

Long hair, jewelry, or loose fitting clothing may get

tangled in moving parts.

4.

Do not change speed limit settings or overspeed the

drive motors.

6.2

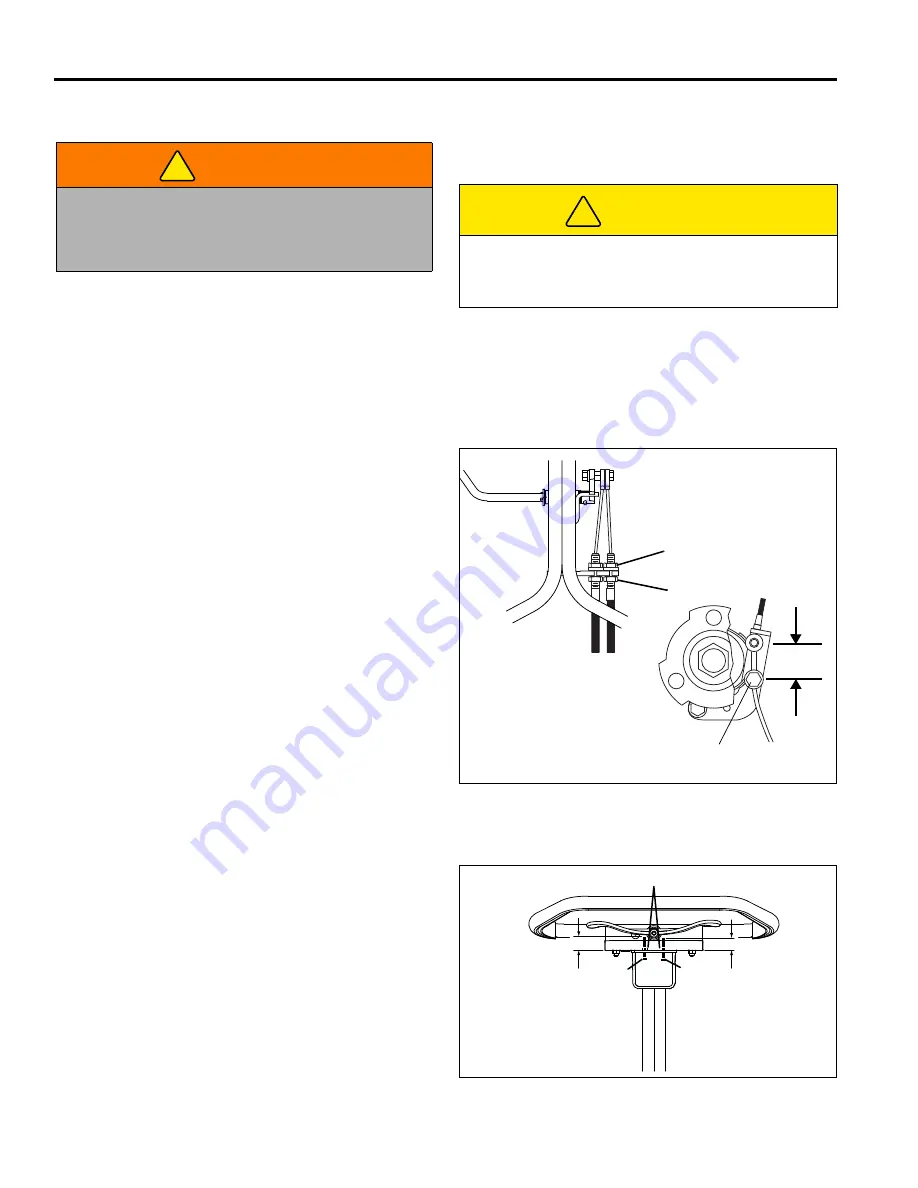

BRAKE __________________________________________________________________

A properly adjusted brake requires 10 lbs. pull at top of

brake lever to engage and must have 1-1/2” (38 mm)

center to center when released.

1.

Minor adjustments are made at the handle. Loosen

nut

(A)

, turn nut

(B)

to adjust the brake cable, then

tighten nut

(A)

.

2.

If adjustments cannot be made at the handle,

remove the transport wheel, and make the

adjustment at the brake band.

3.

Loosen screw

(C)

and pull cable to obtain desired

brake tension. Tighten screw

(C)

. Readjust

(A)

and

(B)

.

Figure 6A

6.3

SPEED PADDLE STOPS ____________________________________________________

1.

Loosen both nuts

(X)

.

2.

Adjust positive paddle stop

(Y)

to 7/8 in. (22 mm).

3.

Adjust negative paddle stop

(Z)

to 1-1/16 in. (27

mm).

4.

Tighten nuts

(X)

to lock adjustment.

After adjusting paddle stops, the controller speed paddle

calibration must be reset.

[See Section 2.3].

Figure 6B

WARNING

Before you adjust, clean, or repair this equipment,

always disengage all drives, engage parking brake,

turn key switch OFF, and disconnect power connector

to prevent serious injury.

!

CAUTION

Be careful to prevent entrapment of the hands and

fingers between moving and fixed components of the

machine.

!

HANDLE

BRAKE BAND

A

B

C

1-1/2”

(38 mm)

1-1/16 in.

(27 mm)

7/8 in.

(22 mm)

X

Y

Z

Summary of Contents for eclipse 2 InCommand

Page 42: ...11 NOTES 42 11 NOTES...