9 ADJUSTMENTS

46

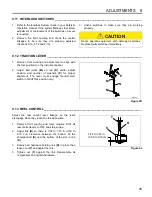

9.14 REEL SWITCHES __________________________________________________________

The reel lever linkage actuates two electrical switches

located under the levers. Check that both switches are

closed when all reel levers are in their NEUTRAL

position.

1.

Check and make sure switches are wired correctly.

Refer to Figure 9M and labels attached to wires for

correct terminal placement.

2.

When any of the reel levers are moved to the

forward position, Reel Switch (Wires A and B)

should open, and Backlap Switch (Wires C and D)

should remain closed.

3.

When any of the reel levers are moved to the

reverse position, Backlap Switch (Wires C and D)

should open and Reel Switch (Wires A and B)

should remain closed.

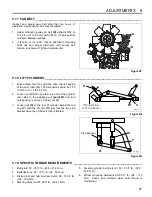

9.15 LEVELING PROCEDURE ___________________________________________________

1.

Lower the implements until they are about 1/4 in.

(0.635 cm) above the ground. If they are not level

with the ground, adjust torsion spring (Z).

2.

Carefully loosen spring mounting clamp and slowly

turn clamp until implement is level. Tighten clamp

securely.

Figure 9N

9.16 REEL BEARING ___________________________________________________________

Excessive end play or any radial play indicates bad

bearings, a weak tension spring, or a backed off nut.

1.

Check bearing housing mounting hardware. Tighten

or replace components as required. Carefully clean

threads with degreaser.

2.

Apply a medium strength grade of Loctite to nut

(AA), then thread nut onto the reel shaft until the nut

is 1-27/32 in. (4.6 cm) from the end of the reel

shaft.

3.

Fill reel bearing housings with NLGI - Grade O

grease after adjusting spring.

Figure 9O

A

B

C

D

Reel Switch

Backlap Switch

WARNING

The torsion spring is under extreme tension and will

tend to uncoil very rapidly if the clamp is loosened. To

prevent being cut by clamp or spring, unwind spring

by tapping on clamp while slowly loosening nut.

!

Z

Clamp

GKV-10

GKV-11

AA

AA

1-27/32 in.

(4.6 cm )