3 ADJUSTMENTS

8

3

ADJUSTMENTS

3.1 GENERAL________________________________________________________________

1. Adjustments and maintenance should always be

performed by a qualified technician. If proper

adjustment cannot be made, contact an authorized

Jacobsen Dealer.

2. Replace, do not adjust, worn or damaged

components.

3. Long hair, jewelry or loose fitting clothing may get

tangled in moving parts.

4. Do not change governor settings or overspeed the

engine.

3.2

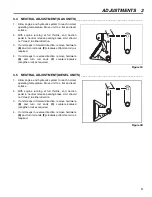

FAN BELT (DIESEL ENGINES) _______________________________________________

Inspect and adjust new belt after first ten hours of

operation. Adjust every 100 hours thereafter.

1. Adjust alternator pulley so belt (

B

) deflects 9/32 to

11/32 in. (7 to 9 mm) with a 22 lb. (10 kgf) push at

midspan between pulleys.

2. If tension is incorrect, loosen alternator mounting

bolts (

A

) and adjust alternator until proper belt

tension is achieved. Tighten hardware (

A

).

Figure 3A

3.3

NEUTRAL SWITCH ________________________________________________________

1. Place traction pedal in neutral position, engage

parking brake.

2. Adjust switch

(C)

and bracket

(D)

as required until

sensing portion of switch is centered under damper

mounting hardware.

3. Use a meter to be certain switch contacts are

closed with pedal in neutral position and open when

pedal is depressed in either the forward or reverse

direction.

Figure 3B

WARNING

To prevent injury, lower implements to the ground,

disengage all drives, engage parking brake, stop

engine and remove key from ignition switch before

making any adjustments or performing maintenance.

Make sure the tractor is parked on a solid and level

surface. Never work on a tractor that is supported

only by the jack. Always use jack stands.

If only the front or rear of the tractor is raised, place

chocks in front of and behind the wheels that are not

raised.

!

CAUTION

Be careful to prevent entrapment of the hands and

fingers between moving and fixed components of the

machine.

!

A

B

C

D